The service life of small electromagnetic clutch brakes is related to these factors

Release time:

2022-01-24

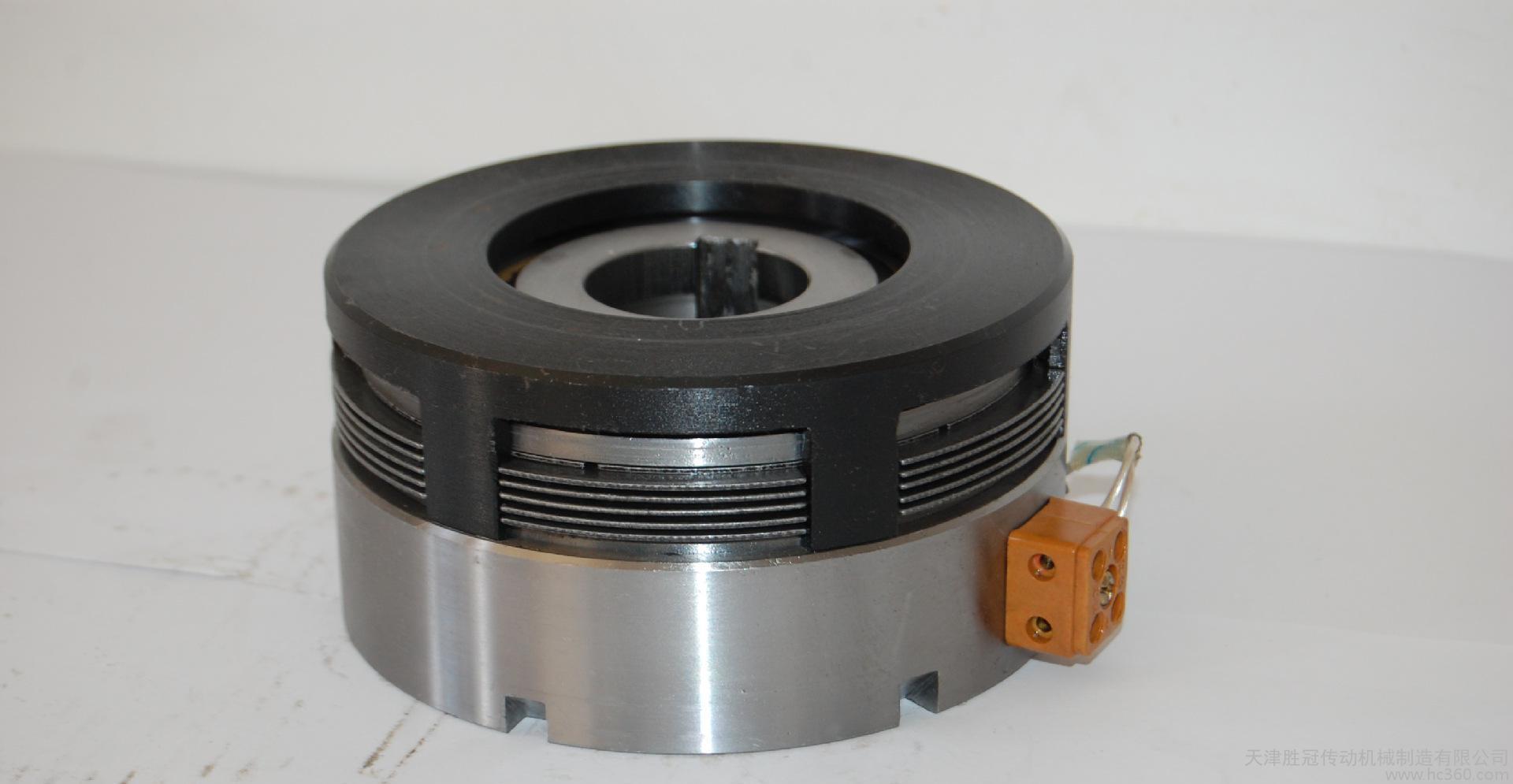

Small electromagnetic clutch and electromagnetic brake are general transmission equipment, widely used in printing machinery, packaging machinery, automation equipment, machine tools and other fields. The above-mentioned machinery in these industries needs to be applied to small electromagnetic clutches and brakes in transmission equipment, and the use of guarantees is even more necessary in the application process. For example, the service life of small electromagnetic clutches and brakes is one of the guarantees.

Small electromagnetic clutch and electromagnetic brake are general transmission equipment, widely used in printing machinery, packaging machinery, automation equipment, machine tools and other fields. The above-mentioned machinery in these industries needs to be applied to small electromagnetic clutches and brakes in transmission equipment, and the use of guarantees is even more necessary in the application process. For example, the service life of small electromagnetic clutches and brakes is one of the guarantees.

So how to ensure the service life of small electromagnetic clutch and electromagnetic brake? From the following direction:

1. It is related to the friction material of electromagnetic brake and small electromagnetic clutch. The use of new friction materials is better than traditional friction materials.

2. It is related to load characteristics, dynamic load torque and static load torque. Large load, sudden addition and incomplete unloading modes will also have a great impact on the service life of electromagnetic clutches and electromagnetic brakes.

3. It is related to the action reaction time of the small electromagnetic clutch and electromagnetic brake, that is, the power-on and power-off release time should be short, otherwise the service life of the electromagnetic clutch brake will be shortened.

4. It is related to the service life of the brush material. High-quality brush materials can extend the service life of electromagnetic clutches and electromagnetic brakes.

It should be noted that the installation position of small electromagnetic clutch and electromagnetic brake should not be close to the place where there is oil and lubricating oil splash.

The working mode of small electromagnetic clutch can be divided into power-on combination and power-off combination. Electromagnetic clutches are generally used in media with ambient temperature -20-50%, humidity less than 85%, and no explosion hazard. The coil voltage fluctuation shall not exceed ± 5% of the rated voltage. Dry single-plate electromagnetic clutch: When the coil is energized, magnetic force is generated to pull into the "armature" disc, and the clutch is in the engaged state; when the coil is de-energized, the "armature" rebounds and the clutch is in the disengaged state.

The armature structure of the small electromagnetic clutch is designed in various forms and is suitable for various installation methods; the torque is transmitted through dry friction, the magnetic field is constant, and there is no residual torque; the special friction material with reliable and high switching frequency; low moment of inertia; compact structure, simple installation, Long service life. Electromagnetic clutch is an automatic actuator that transmits or stops torque through the action of electromagnetic force in mechanical transmission.

The small electromagnetic clutch has the advantages of fast response, high durability, easy assembly and maintenance, no wear adjustment, reliable action, and adjustable torque. There is no mechanical connection between the main and driven parts of the electromagnetic clutch, no wear and tear, no magnetic powder leakage, no impact. Adjusting the excitation current can change the speed and use it as a continuously variable transmission, which is its advantage.

In order to ensure the uninterrupted operation of the small electromagnetic clutch, it must be maintained frequently:

1. Always add lubricant to the moving parts of the electromagnetic clutch.

2. Regularly check the length of the armature stroke. Because during clutch operation, the stroke length of the armature will increase due to the wear of the cutting surface. When the armature stroke length fails to reach the normal value, it must be adjusted to restore the small gap between the braking surface and the brake pressure dial. If the armature stroke length increases beyond the normal value, the suction force may be greatly reduced.

Key words:

Small electromagnetic clutch

recommend News

The role of electromagnetic brake

2022-10-28

Regarding the difference between energized brakes and non-energized electromagnetic brakes, many users do not know the working principle of these two electromagnetic brakes and the difference between the two. Then, let's learn about the role of electromagnetic brakes!

Introduction and Application of Electromagnetic Brake

2022-10-18

Electromagnetic brakes are mainly matched with series motors and are widely used in the metallurgical industry. Construction. The chemical industry. Food. Machine tools. Phase. The elevator. Vessels. Packaging machinery and braking in the event of electrical failure.

The working principle of electromagnetic brake

2022-10-09

The electromagnetic brake is a connector that transmits torque from the active side to the passive side. Any combination of cutting or braking can be required. The electromagnetic brake has compact structure, simple operation, sensitive response and easy to realize remote control.

The company has a product research and development department composed of experts, senior engineers and other professional and technical personnel. It is engaged in research and development and has perfect research and development test equipment. At present, the products reach more than 100 series of nearly 1,000 specifications, and the force distance ranges from 0.1N. m ~ 250000N.m. The company has been rated as a high-tech enterprise by the state for more than ten consecutive years, and a number of R & D projects have been established locally and have received municipal financial support.

Service Hotline:

Sales Department: Xu Jie

Sales Phone:+86-22-26616372, +86-22-26341260, +86 13920613215

Fax: 86-022-26616580

Market Development Department: Li Shuo

Marketing Department Telephone:+86-22-26614130

Technology Department: Yue Chao

Technical Department Telephone:+86-22-26222775 ,+86 18602228435

QQ:1059237223 1611412939

Company Website:www.tjlhq.com

Enterprise E-mail:xzm@tjlhq.com

Company address: No.6, Zone B, South Jifeng Road, Hongcang City Industrial Park, Yanji Daohong, Beichen District, Tianjin