Do you know the characteristics of electromagnetic clutch? How to extend its life?

Release time:

2022-02-28

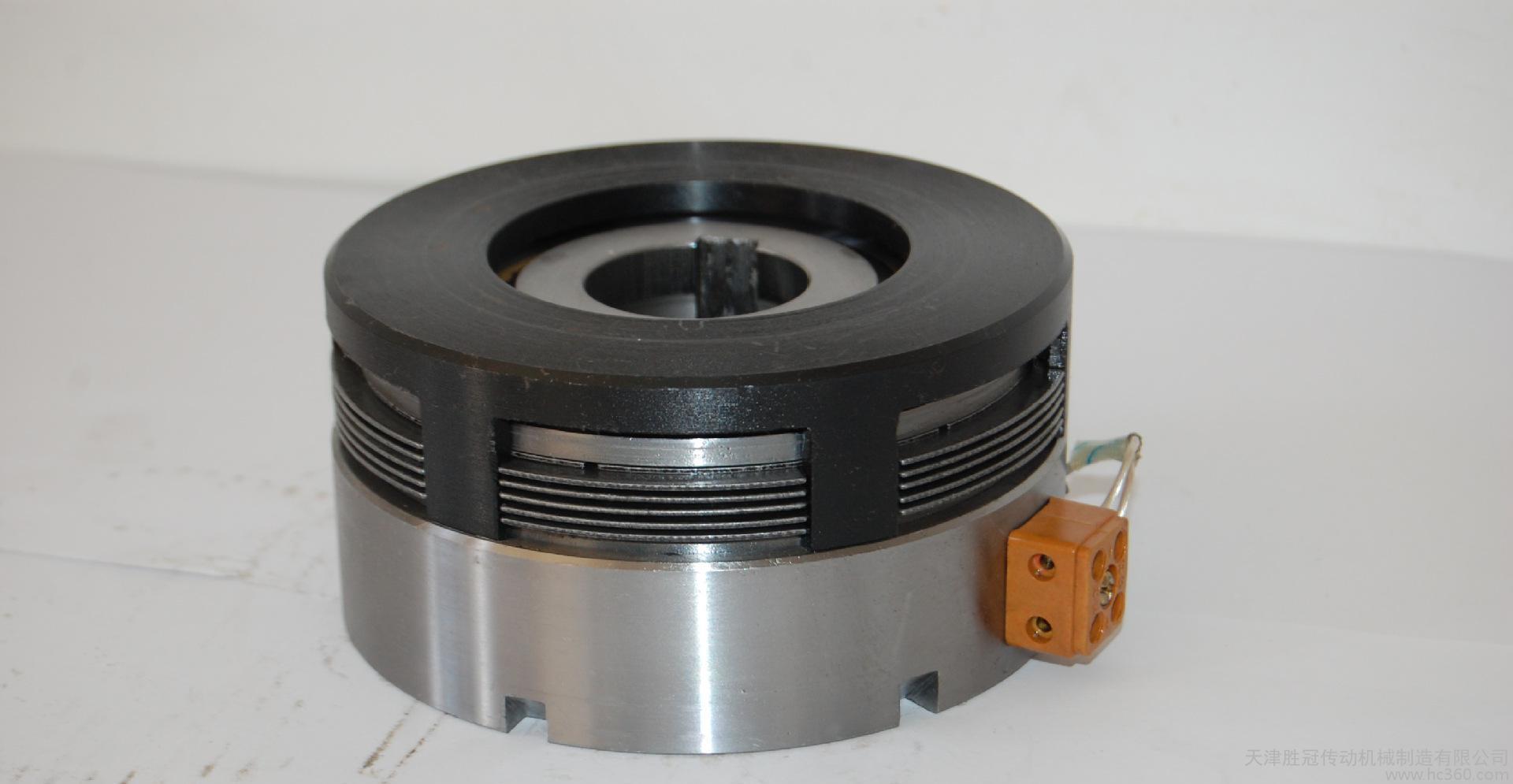

When purchasing products such as electromagnetic clutches, the price of electromagnetic clutches has become one of the reference standards. The price of a good quality electromagnetic clutch will definitely be higher than that of an ordinary clutch. As an important part of electromechanical products, electromagnetic clutch plays a role in transmitting power and controlling motion in mechanical transmission system.

When purchasing products such as electromagnetic clutches, the price of electromagnetic clutches has become one of the reference standards. The price of a good quality electromagnetic clutch will definitely be higher than that of an ordinary clutch. As an important part of electromechanical products, electromagnetic clutch plays a role in transmitting power and controlling motion in mechanical transmission system. Therefore, when choosing an electromagnetic clutch, we should not only pay attention to the price of the electromagnetic clutch, but ignore its true strength. The electromagnetic clutch is easy to realize remote centralized operation and automatic control. He can also realize multiple functions such as connection, separation, braking, positioning braking, shifting, reversing, inching, and overload protection through certain design and auxiliary cooperation.

Dry electromagnetic clutch is one of its unique functional types. Its unique functions include: forward and reverse operation, using the electromagnetic clutch to switch the rotation direction of the load, so that the load moves back and forth without changing the rotation direction of the moving parts; for high-frequency operation, the electromagnetic clutch manufacturers find that it can only be controlled by the switch of the motor, So it can only be controlled by loading the electromagnetic clutch and electromagnetic brake. The clutch of the electromagnetic clutch manufacturer acts as a buffer for start and stop, reducing the impact on the load. When moving or stopping, the large friction force is reduced. When the adjustment torque reaches this point, the heat dissipation is prone to errors. When inching, starting or adjusting the machine, try to shorten the slip time of the electromagnetic clutch. The inching motion is realized by the brake and the electromagnetic brake.

If there is noise in use, the manufacturer of the electromagnetic clutch will tell you how to do it. First check whether the friction plate is damaged: check whether the material attached to the friction plate or the rivet head used to rivet the friction plate is normal. If an abnormal situation occurs, the friction plate will fall off, which may cause direct metal-to-metal contact during braking. This will not only affect the safe braking distance, but also cause greater damage to the rotor surface. In this case, it is necessary to replace the friction plate with a new friction plate and repair the damaged rotor accordingly.

Electromagnetic clutch and brake are general transmission equipment, in the industry gradually automation today, widely used in packaging machinery, printing machinery, automation equipment, machine tools and other fields. The above-mentioned industrial machinery requires clutches and brakes applied to transmission equipment, which need to be properly operated to ensure the service life of the clutches and electromagnetic brakes.

So how to ensure the service life of electromagnetic clutches and brakes? The manufacturers of electromagnetic clutches give some good suggestions to help people solve the problem of short life:

1. Related to the friction materials of electromagnetic brakes and clutches, the service life of the new friction materials is longer than that of traditional friction materials.

It is related to load characteristics, dynamic load moment and static load moment. Overload, burst, and incomplete unload modes. It also has a great impact on the service life of electromagnetic clutches and brakes.

3. It is related to the action reflection time of the clutch and electromagnetic brake, that is, the time for energy absorption and power failure should be shorter, otherwise it will shorten the service life of the clutch brake.

4. The quality of the brush material is related to the service life of the brush material, which can extend the service life of the clutch and brake. It should be noted that the installation position of the electromagnetic clutch and brake should not be close to the splash position of grease and lubricant.

5. The electromagnetic clutch and electromagnetic brake can be installed on the coaxial or butt shaft. When installed on the shaft, the coaxiality of the two shafts must be guaranteed. When installing the electromagnetic clutch and electromagnetic brake, it should be noted that there should be no friction between the yoke and the moving plate. The gap between the movable plate and the armature should be within the size range specified in the table.

In addition, the use of electromagnetic clutch should try to avoid lubricating oil and other oil, especially oil should not pollute the electromagnetic clutch and electromagnetic brake components.

Key words:

Electromagnetic clutch

recommend News

The role of electromagnetic brake

2022-10-28

Regarding the difference between energized brakes and non-energized electromagnetic brakes, many users do not know the working principle of these two electromagnetic brakes and the difference between the two. Then, let's learn about the role of electromagnetic brakes!

Introduction and Application of Electromagnetic Brake

2022-10-18

Electromagnetic brakes are mainly matched with series motors and are widely used in the metallurgical industry. Construction. The chemical industry. Food. Machine tools. Phase. The elevator. Vessels. Packaging machinery and braking in the event of electrical failure.

The working principle of electromagnetic brake

2022-10-09

The electromagnetic brake is a connector that transmits torque from the active side to the passive side. Any combination of cutting or braking can be required. The electromagnetic brake has compact structure, simple operation, sensitive response and easy to realize remote control.

The company has a product research and development department composed of experts, senior engineers and other professional and technical personnel. It is engaged in research and development and has perfect research and development test equipment. At present, the products reach more than 100 series of nearly 1,000 specifications, and the force distance ranges from 0.1N. m ~ 250000N.m. The company has been rated as a high-tech enterprise by the state for more than ten consecutive years, and a number of R & D projects have been established locally and have received municipal financial support.

Service Hotline:

Sales Department: Xu Jie

Sales Phone:+86-22-26616372, +86-22-26341260, +86 13920613215

Fax: 86-022-26616580

Market Development Department: Li Shuo

Marketing Department Telephone:+86-22-26614130

Technology Department: Yue Chao

Technical Department Telephone:+86-22-26222775 ,+86 18602228435

QQ:1059237223 1611412939

Company Website:www.tjlhq.com

Enterprise E-mail:xzm@tjlhq.com

Company address: No.6, Zone B, South Jifeng Road, Hongcang City Industrial Park, Yanji Daohong, Beichen District, Tianjin