The use conditions and working principle of single-plate electromagnetic clutch

Release time:

2022-04-29

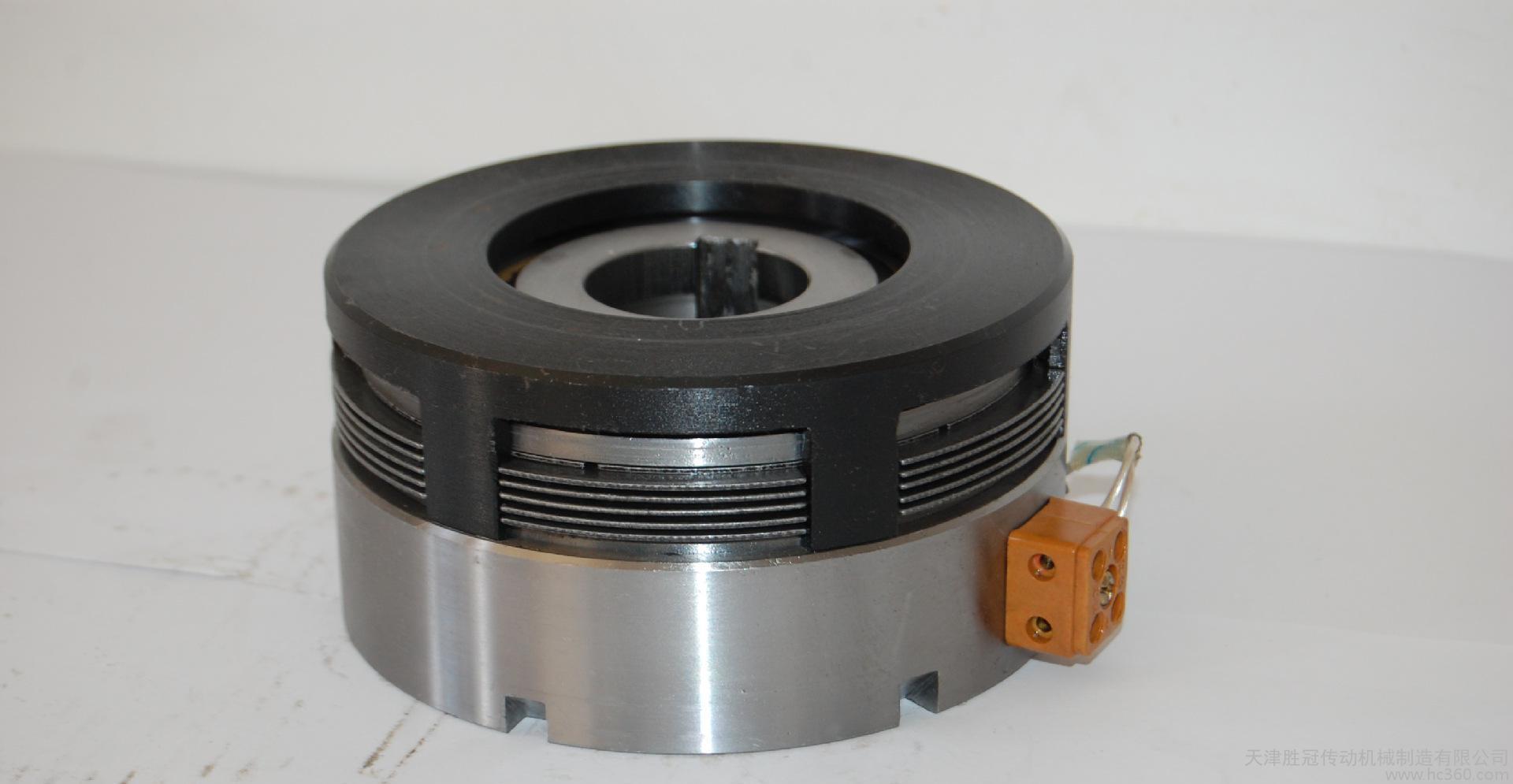

The single-plate electromagnetic clutch is mainly composed of yoke, rotor, armature, spring plate and flange. When the coil is energized, the magnetic field generated by the yoke attracts the friction torque generated by the armature and the armature, so that the driven part is combined or separated, and the spring piece with a special shape is reset. The structure is simple, the delay time of connection and separation is short, and the braking torque is large. Suitable for mechanical transmission system in the need of clutch or positioning occasions.

single-plate electromagnetic clutchIt is mainly composed of yoke, rotor, armature, spring plate and flange. When the coil is energized, the magnetic field generated by the yoke attracts the friction torque generated by the armature and the armature, so that the driven part is combined or separated, and the spring piece with a special shape is reset. The structure is simple, the delay time of connection and separation is short, and the braking torque is large. Suitable for mechanical transmission system in the need of clutch or positioning occasions.

1.single-plate electromagnetic clutchWorking conditions:

1. Work under dry conditions;

2. In the surrounding medium, there is no gas and conductive dust sufficient to corrode the metal and damage the insulation;

3.Working environment temperature-40~150, friction plate and armature surface shall be free of oil,NeedKeep clean;

4. The insulation class is B, the protection class is IP23, and the voltage fluctuation range is less than 5% and-15%;

5. The working air gap shall not exceedLimitLarge working air gap. The master and slave sides of the brake shall be fixed and no axial movement is allowed;

6. Installation method: axial horizontal vertical installation. When installing the brake, the coaxial lineNeednot greater0.1mm:

7. Working mode: intermittent work and continuous work.

2Single-plate electromagnetic clutchThe working principle

single-plate electromagnetic clutchUsing spline transmission, with automatic gap adjustment device, large heat dissipation and good durability. The electromagnetic clutch coil is supported by the bearing, so it is easy to assemble. Due to the automatic gap adjustment device, there is no need to use shims for gap adjustment during assembly, and the assembly direction is not limited, both vertical and horizontal.

Can be installed; fast response, short torque build-up time, fast elimination, clear action; diverse specifications, large torque selection range,12-1000Nm optional non-asbestos friction material.

single-plate electromagnetic clutch: When the clutch is working, the master-slave partNeedThere is a certain speed difference to transmit torque. The torque depends on the magnetic field strength and the speed difference. The excitation current remains unchanged, and the speed drops sharply with the increase of torque. When the torque remains unchanged, the excitation current decreases and the speed drops more severely. There is no mechanical connection between the main and driven parts of the slip electromagnetic clutch, no wear, no magnetic powder leakage, and no impact. Adjusting the excitation current can change the speed and make it a continuously variable transmission, which is its advantage. The main disadvantage of this clutch is that the eddy current in the rotor generates heat, which is proportional to the speed difference.

dry typesingle-plate electromagnetic clutch: When the coil is energized, a magnetic force is generated. Under the action of electromagnetic force, the spring sheet of the armature deforms, and the moving sheet andThe "armature" attracts each other to engage the clutch; the coil is de-energized, the magnetic force disappears, the "armature" bounces back under the action of the spring force, and the clutch is in a disengaged state. Dry multi-disc wet multi-disc electromagnetic clutch: the principle is the same as above, a few more friction pairs are added, so the torque of the same volume is better than drysingle-plate electromagnetic clutchLarge, wet multi-disc electromagnetic clutch when workingNeedCooling and lubrication with oil.

Key words:

Single-plate electromagnetic clutch

recommend News

The role of electromagnetic brake

2022-10-28

Regarding the difference between energized brakes and non-energized electromagnetic brakes, many users do not know the working principle of these two electromagnetic brakes and the difference between the two. Then, let's learn about the role of electromagnetic brakes!

Introduction and Application of Electromagnetic Brake

2022-10-18

Electromagnetic brakes are mainly matched with series motors and are widely used in the metallurgical industry. Construction. The chemical industry. Food. Machine tools. Phase. The elevator. Vessels. Packaging machinery and braking in the event of electrical failure.

The working principle of electromagnetic brake

2022-10-09

The electromagnetic brake is a connector that transmits torque from the active side to the passive side. Any combination of cutting or braking can be required. The electromagnetic brake has compact structure, simple operation, sensitive response and easy to realize remote control.

The company has a product research and development department composed of experts, senior engineers and other professional and technical personnel. It is engaged in research and development and has perfect research and development test equipment. At present, the products reach more than 100 series of nearly 1,000 specifications, and the force distance ranges from 0.1N. m ~ 250000N.m. The company has been rated as a high-tech enterprise by the state for more than ten consecutive years, and a number of R & D projects have been established locally and have received municipal financial support.

Service Hotline:

Sales Department: Xu Jie

Sales Phone:+86-22-26616372, +86-22-26341260, +86 13920613215

Fax: 86-022-26616580

Market Development Department: Li Shuo

Marketing Department Telephone:+86-22-26614130

Technology Department: Yue Chao

Technical Department Telephone:+86-22-26222775 ,+86 18602228435

QQ:1059237223 1611412939

Company Website:www.tjlhq.com

Enterprise E-mail:xzm@tjlhq.com

Company address: No.6, Zone B, South Jifeng Road, Hongcang City Industrial Park, Yanji Daohong, Beichen District, Tianjin