Working principle and performance characteristics of 24V electromagnetic power loss brake

Release time:

2022-06-30

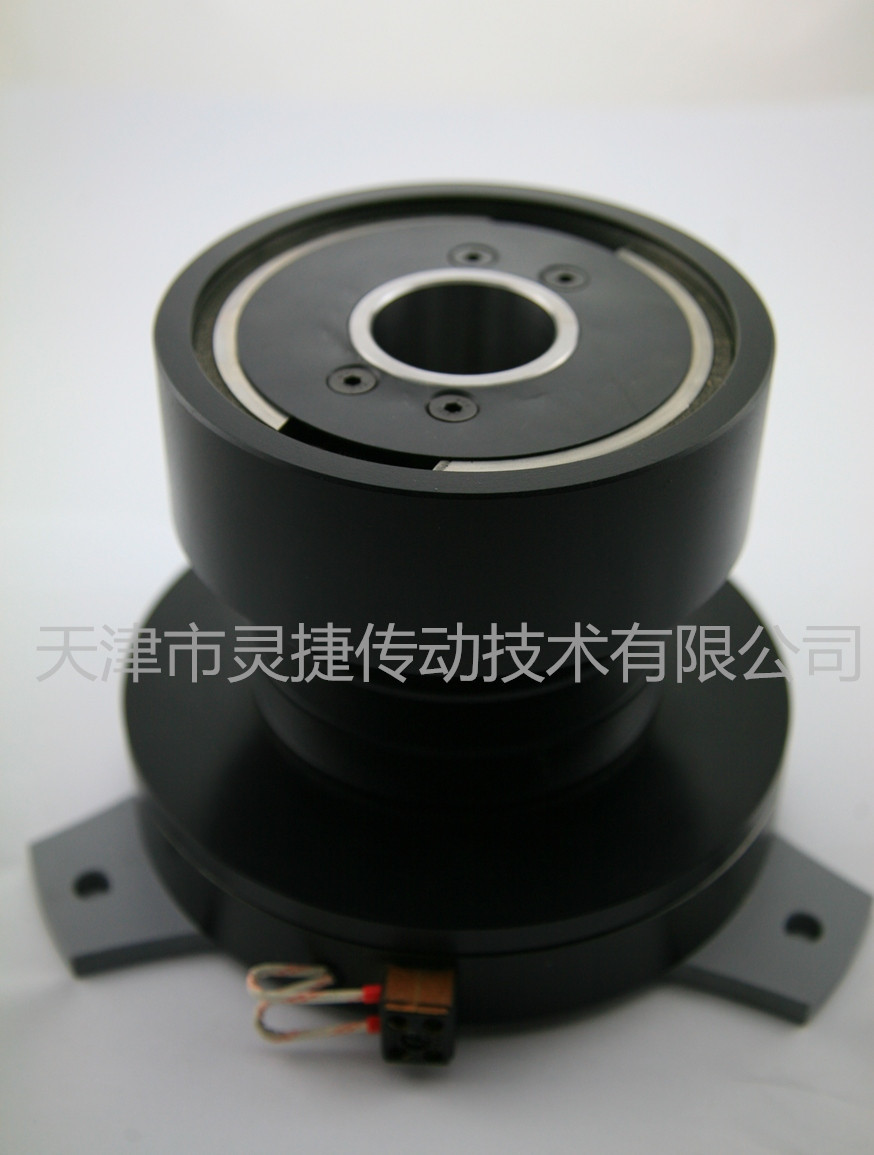

The working principle and performance characteristics of the 24V electromagnetic power loss brake, the company's 24V electromagnetic power loss brake is described as follows: 24V electromagnetic power-off brake has the advantages of simple structure, low noise and reliable braking. Ideal implementation elements of industrial modernization. With its characteristics, the electrostatic brake meets the needs of robots, motors and other machines for different purposes.

The working principle and performance characteristics of the 24V electromagnetic power loss brake, the company's 24V electromagnetic power loss brake is described as follows:

24V electromagnetic power-off brake has the advantages of simple structure, low noise and reliable braking. Ideal implementation elements of industrial modernization. With its characteristics, the electrostatic brake meets the needs of robots, motors and other machines for different purposes.

24V electromagnetic power loss brake mainly has the following characteristics:

1. The structure is compact, the axial dimension of the electrostatic brake is small, but the braking torque is large enough.

2. Quick response: The electrostatic brake selects the stretching device to form the braking torque, and the moment of stretching and resetting is the braking sound.

3. The life of the time is better: the electrostatic brake chooses the new conflict material. Electrical loss The electromagnetic brake is composed of a yoke, an excitation coil, an extension spring, a brake disc, an armature, a spline sleeve, and nails for the device. The manual release brake brake extends from the flange (or motor) of the device. The drive axle and spline sleeve are connected to the brake disc.

The excitation coil of the 24V electromagnetic power-off brake is connected to additional voltage (DC). When the electromagnetic force is separated from (loosened) the brake disc, the drive shaft has the brake disc to work or start normally, and the drive system is separated or powered off. The brake is also powered off together. At this time, the tension spring applies pressure to the armature, generating conflicting torque between the brake disc, the armature and the flange, making the drive shaft fast.

When the 24V electromagnetic power loss brake is in a bad thermal environment and the drive shaft works continuously for a long time, the voltage can be switched to an additional voltage of 70%-80% after the brake works, thereby reducing heat.

Structure of 24V electromagnetic power loss brake

1. According to the difference of the gap, it can be divided into hollow screw structure and sleeve structure. The brake with a hollow screw structure can adjust the spacing as needed. The advantage is that it can be adjusted multiple times after the friction plate is worn during use. The life of the brake is greatly increased, and it is often used for deceleration braking. The brake with the lining structure cannot be adjusted manually after assembly. The advantage is that it is easy to install and can maintain the brake.

2. According to whether there is a separate handle, it can be divided into a structure with a separate handle and a structure without a separate handle. The brake has a separate handle. If the device fails or the power is turned off, this handle will release the brake to facilitate maintenance of the device or move it to a safe position.

3. According to the adjustability of the torque, it can be divided into torque adjustment brakes and non-adjustable brakes. Torque adjustment brakes are mainly used in situations where high torque accuracy is required.

The electromagnetic brake consists of a compression spring, which contacts the end of the armature in a slot, iron, cover, and slot spring hole with winding coils, and is located between the armature and the cover, as shown in the figure below.

After the coil passes the rated voltage of the winding, the armature compresses the torque spring under the action of electromagnetic force and is adsorbed on the end surface of the slot. At this time, the rotor is released and can rotate freely. After the power is off, the electric iron presses the rotor between the armature and the cover under the action of the spring force, and the motor brakes under the action of friction.

Key words:

Electromagnetic power-off brake

recommend News

The role of electromagnetic brake

2022-10-28

Regarding the difference between energized brakes and non-energized electromagnetic brakes, many users do not know the working principle of these two electromagnetic brakes and the difference between the two. Then, let's learn about the role of electromagnetic brakes!

Introduction and Application of Electromagnetic Brake

2022-10-18

Electromagnetic brakes are mainly matched with series motors and are widely used in the metallurgical industry. Construction. The chemical industry. Food. Machine tools. Phase. The elevator. Vessels. Packaging machinery and braking in the event of electrical failure.

The working principle of electromagnetic brake

2022-10-09

The electromagnetic brake is a connector that transmits torque from the active side to the passive side. Any combination of cutting or braking can be required. The electromagnetic brake has compact structure, simple operation, sensitive response and easy to realize remote control.

The company has a product research and development department composed of experts, senior engineers and other professional and technical personnel. It is engaged in research and development and has perfect research and development test equipment. At present, the products reach more than 100 series of nearly 1,000 specifications, and the force distance ranges from 0.1N. m ~ 250000N.m. The company has been rated as a high-tech enterprise by the state for more than ten consecutive years, and a number of R & D projects have been established locally and have received municipal financial support.

Service Hotline:

Sales Department: Xu Jie

Sales Phone:+86-22-26616372, +86-22-26341260, +86 13920613215

Fax: 86-022-26616580

Market Development Department: Li Shuo

Marketing Department Telephone:+86-22-26614130

Technology Department: Yue Chao

Technical Department Telephone:+86-22-26222775 ,+86 18602228435

QQ:1059237223 1611412939

Company Website:www.tjlhq.com

Enterprise E-mail:xzm@tjlhq.com

Company address: No.6, Zone B, South Jifeng Road, Hongcang City Industrial Park, Yanji Daohong, Beichen District, Tianjin