Industry Applications

Procurement Guide

We have more professional advice and guidelines available by phone+86-22-26616372Column

Can also beMessageGive usWe will get in touch with you the first time!

DLM9 Series (ERD Series) Wet Multi-disc Electromagnetic Clutch without Slip Ring

- Details

-

The electromagnetic clutch is a friction clutch in which a pressing force is generated by an electromagnetic force. Because it can realize long-distance control, small control energy, easy to realize machine tool automation, fast action, simple structure, and has been widely used. Electromagnetic clutch is also called electromagnetic coupling. It is an electromagnetic mechanical connector that applies the principle of electromagnetic induction and the friction between the inner and outer friction plates to make the two rotating parts in the mechanical transmission system. When the active part does not stop rotating, the driven part can be combined or separated with it., Is an automatic electrical appliance. The electromagnetic clutch can be used to control the starting, reverse, speed regulation and braking of the machine.

Installation matters

1. Please use the dry electromagnetic clutch when there is no moisture, oil, etc., if the friction part is stained with moisture or oil, etc.

The friction torque will be greatly reduced, and the sensitivity of the clutch will also become worse. In order to avoid these situations in use, please add a cover.

2. Please use a protective cover when using it in a place with a lot of dust.

3. Please use JIS0401 H6 or JS6 for the long axis size of the clutch. Use one of the keys specified in the JIS B1301-1959 for mounting the shaft.

Taking into account the thermal expansion and other factors, the thrust of the installation shaft should be selected below 0.2MM.

5. During installation, please adjust the suction gap mechanically to within plus or minus 20% of the specified value.

6. Please keep the bracket light and do not use the bearing of the clutch to bear excessive pressure.

7. For the screws used for assembly, please use spring metal sheet, adhesive, etc. to prevent loosening.

8, the use of the mechanical side of the frame to maintain the lead at the same time, but also the use of terminal plates and other real connection.

Main performance parameters

Main Technical Data

Specifications

ModelRated dynamic torque

Rated Torque

N.MRated static moment

Rated Static Torque

N.Mno-load moment

Drag Torque

(≦) N.mOn time

Engagement Time

(≦)SDisconnection time

Disengagement

(≦)SRated voltage

Rated Voltage

D.C.VCoil power consumption (20 ℃)

CoilPower

(20℃)WMaximum allowable speed

Max Allowed Speed

r/minWeight

Weight

KgOil supply flow

Oil Flow Rates

L/min2

16

25

0.48

0.28

0.09

24

24

3000

2.9

0.25

5

50

80

0.85

0.30

0.10

24

37

3000

3.9

0.40

10

100

160

1.80

0.32

0.14

24

50

3000

5.9

0.65

16

160

250

2.40

0.36

0.16

24

53

2500

7.8

0.65

25

250

400

3.80

0.40

0.18

24

76

2200

10.7

1.00

40

400

630

6.00

0.60

0.22

24

86

2000

15

1.00

63

630

1000

9.50

0.70

0.26

24

88

1800

22

1.20

100

1000

1600

15.00

0.85

0.31

24

104

1600

33

1.20

160

1600

2500

24.00

1.20

0.43

24

122

1500

23.2

1.50

250

2500

4000

38.00

1.40

0.50

24

175.5

1200

67

2.00

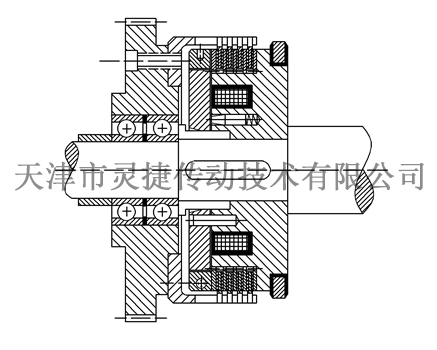

Installation Schematic

Installation Diagram

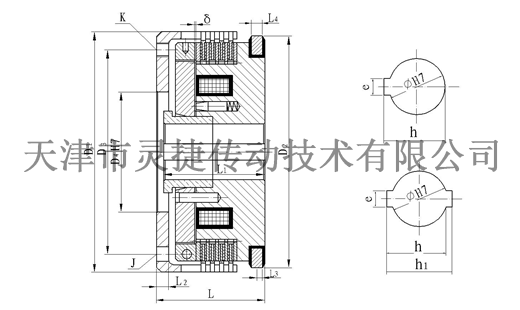

Outline and installation dimensions

Shape and Installation Dimensions

Specifications Model

Radial Dimensions

Axial dimension Radial Dimensions

D1

D2

D3

D4

Φ

e

h

j

k

L

L1

L2

S

T

2

95

80

35

50

20

6

22.80 0.1

2xφ6

4Xm6

55

50

5

4

8

5

110

90

45

65

30

8

33.30 0.2

3xφ6

4Xm6

60

55

5

4

8

10

132

105

50

75

40

12

42.30 0.2

3xφ6

6XM8

67

60

7

5

10

16

147

120

55

85

45

14

47.40 0.2

3xφ8

6XM8

72

65

7

5

10

25

162

135

65

95

50

16

53.60 0.2

3xφ8

6XM8

82

75

7

6

12

40

182

155

75

120

60

18

64.40 0.2

3xφ10

6XM10

93

85

8

6

12

63

202

170

85

125

70

20

74.30 0.2

3xφ10

6XM10

109

100

9

8

14

100

235

200

100

150

70

20

74.90 0.2

3xφ14

6XM12

120

110

10

8

14

160

270

235

110

200

90

25

95.40 0.2

3xφ14

6XM12

142

130

12

10

16

250

310

260

140

220

110

28

116.40 0.2

3xφ16

6XM16

157

145

14

10

16

Key words:

The company has a product research and development department composed of experts, senior engineers and other professional and technical personnel. It is engaged in research and development and has perfect research and development test equipment. At present, the products reach more than 100 series of nearly 1,000 specifications, and the force distance ranges from 0.1N. m ~ 250000N.m. The company has been rated as a high-tech enterprise by the state for more than ten consecutive years, and a number of R & D projects have been established locally and have received municipal financial support.

Service Hotline:

Sales Department: Xu Jie

Sales Phone:+86-22-26616372, +86-22-26341260, +86 13920613215

Fax: 86-022-26616580

Market Development Department: Li Shuo

Marketing Department Telephone:+86-22-26614130

Technology Department: Yue Chao

Technical Department Telephone:+86-22-26222775 ,+86 18602228435

QQ:1059237223 1611412939

Company Website:www.tjlhq.com

Enterprise E-mail:xzm@tjlhq.com

Company address: No.6, Zone B, South Jifeng Road, Hongcang City Industrial Park, Yanji Daohong, Beichen District, Tianjin