Share

- Details

-

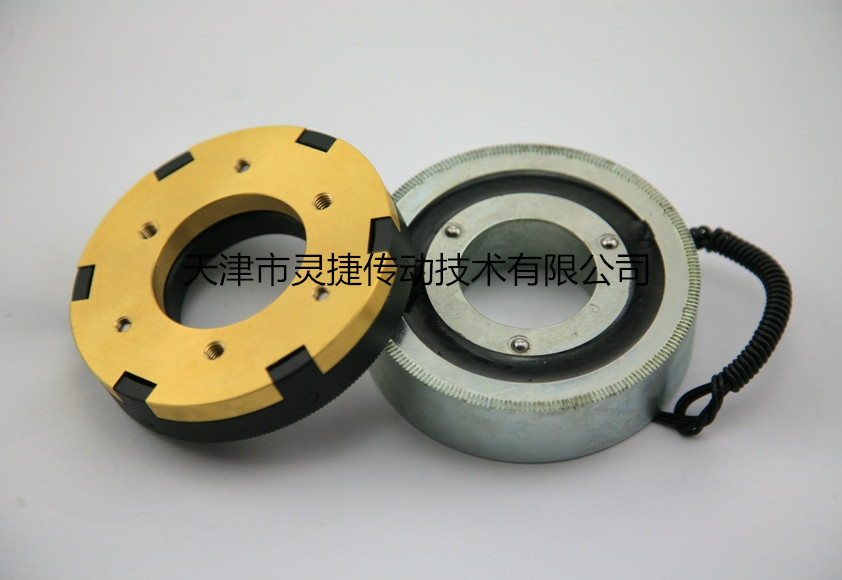

Electromagnetic brake dynamic working principle

1. Control the braking and separation of the power shaft through 24V direct current, power-on braking, power-off separation

2. Shaft plug-in structure, used to control the brake stop and free running of the power shaft

3. Applied to dry oil-free environment

4, the braking time is agile, can be used for high frequency braking occasions. Low noise, low heat

The electromagnetic brake is mainly used in: packaging and packaging machinery: such as packaging machines, bundling machines, packaging machinery, etc. Metal processing machinery: such as calender, stretching machine, punching machine, welding machine, copper wall iron wall wire return machine, cutting machine, pipe making machinery, winding machine, etc.

Adjust the electromagnetic clutch electromagnetic brake clearance method is as follows:

1. Loosen the mounting bolts evenly with a hexagonal wrench;

2. Adjust the hollow screw with a wrench. Pay attention to adjusting the two hollow screws on the same 7-mounting bolt. After tightening the mounting bolt, use a feeler gauge to test the air gap. After passing the test, adjust the air gap at the mounting bolt spaced apart from it until the air gaps at all positions are adjusted to be qualified;

3. Tighten the 7-mounting bolt with a hexagonal wrench after completion;

4. Re-use the feeler gauge to check whether the air gap is qualified. If it is unqualified, repeat step 2 again and readjust until it is adjusted;

5, non-professional personnel is best not to adjust the gap, and can not have oil dripping into the friction plate and do not damage the wire sheath and so on. The above is all the contents of the electromagnetic brake gap adjustment, including but not limited.

Electromagnetic brake is an ideal automation actuator in modern industry, which mainly plays the role of transmitting power and controlling motion in mechanical transmission system. Electromagnetic brake can be divided into electromagnetic powder brake and electromagnetic eddy current brake, electromagnetic friction brake and other forms.Metallurgy, construction, chemical industry, food, machine tools, stage, elevators, ships, packaging and other machinery, and when the power is off (risk prevention) braking and other occasions. Brakes that use electromagnetic effects to achieve braking are divided into electromagnetic powder brakes, electromagnetic eddy current brakes, electromagnetic friction brakes and other forms. ① Electromagnetic powder brakes: When the excitation coil is energized, a magnetic field is formed, and the magnetic powder is magnetized under the action of the magnetic field to form a magnetic powder chain, which is polymerized between the fixed magnetizer and the rotor, and braking is realized by the binding force and friction of the magnetic powder. When the exciting current disappears, the magnetic powder is in a free and loose state, and the braking effect is released. This kind of brake is small in size, light in weight, small in excitation power, and the braking torque has nothing to do with the speed of the rotating parts, but the magnetic powder will cause the parts to wear. It is convenient for automatic control and is suitable for the drive system of various machines. ② Electromagnetic eddy current brake: magnetic field is formed when the exciting coil is energized. The rotation of the armature on the brake shaft cuts the magnetic field lines and generates eddy currents. The eddy currents within the armature interact with the magnetic field to form a braking torque. The electromagnetic eddy current brake is durable, easy to maintain, and has a large speed range; but at low speed, the efficiency is low and the temperature rises, and heat dissipation measures must be taken. This type of brake is often used in machinery with vertical loads. ③Electromagnetic friction brake: The excitation coil is energized to generate a magnetic field, and the armature is attracted by the magnetic yoke, and the armature realizes shaft braking through the coupling flange. It is also subdivided into electromagnetic dry single-plate electromagnetic brake dry multi-plate electromagnetic brake wet multi-plate electromagnetic brake and so on. There are also braking methods that can be divided into power-on braking and power-off braking.

In order to ensure the uninterrupted operation of the electromagnetic brake, it must be maintained and maintained frequently: 1. Lubricant is often added to the movable part of the electromagnetic brake. 2. Regularly check the length of the armature stroke. This is because, during operation of the brake, the stroke length of the armature increases due to wear of the cross-sectional surface. When the armature stroke length does not reach the normal value, it must be adjusted to restore the minimum gap between the braking surface and the turntable. If the armature stroke length is increased above the normal value, the suction force may be greatly reduced. 3. If the worn braking surface is replaced, the minimum clearance between the braking surface and the turntable should be properly adjusted. 4. Always check the tightening degree of the bolts, especially tighten the bolts of the electromagnet, the bolts of the electromagnet and the housing, the bolts of the yoke, the bolts of the electromagnet coil and the terminal bolts. 5. Regularly check the mechanical wear of the movable parts, and remove the dust, flower hair and dirt on the surface of the electromagnet parts.

DZY0 series jaw type electromagnetic brake

Classification

Keyword

Gate control system clutch

- Details

-

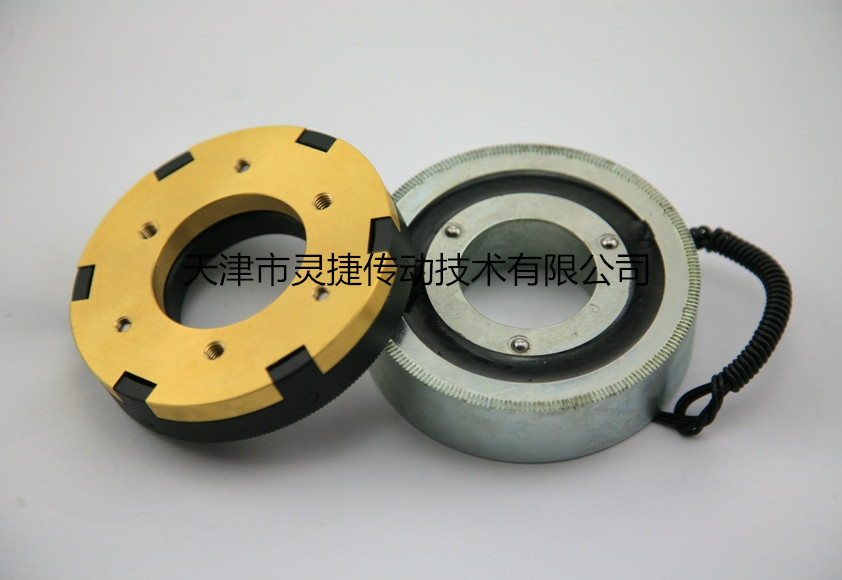

Electromagnetic brake dynamic working principle

1. Control the braking and separation of the power shaft through 24V direct current, power-on braking, power-off separation

2. Shaft plug-in structure, used to control the brake stop and free running of the power shaft

3. Applied to dry oil-free environment

4, the braking time is agile, can be used for high frequency braking occasions. Low noise, low heat

The electromagnetic brake is mainly used in: packaging and packaging machinery: such as packaging machines, bundling machines, packaging machinery, etc. Metal processing machinery: such as calender, stretching machine, punching machine, welding machine, copper wall iron wall wire return machine, cutting machine, pipe making machinery, winding machine, etc.

Adjust the electromagnetic clutch electromagnetic brake clearance method is as follows:

1. Loosen the mounting bolts evenly with a hexagonal wrench;

2. Adjust the hollow screw with a wrench. Pay attention to adjusting the two hollow screws on the same 7-mounting bolt. After tightening the mounting bolt, use a feeler gauge to test the air gap. After passing the test, adjust the air gap at the mounting bolt spaced apart from it until the air gaps at all positions are adjusted to be qualified;

3. Tighten the 7-mounting bolt with a hexagonal wrench after completion;

4. Re-use the feeler gauge to check whether the air gap is qualified. If it is unqualified, repeat step 2 again and readjust until it is adjusted;

5, non-professional personnel is best not to adjust the gap, and can not have oil dripping into the friction plate and do not damage the wire sheath and so on. The above is all the contents of the electromagnetic brake gap adjustment, including but not limited.

Electromagnetic brake is an ideal automation actuator in modern industry, which mainly plays the role of transmitting power and controlling motion in mechanical transmission system. Electromagnetic brake can be divided into electromagnetic powder brake and electromagnetic eddy current brake, electromagnetic friction brake and other forms.Metallurgy, construction, chemical industry, food, machine tools, stage, elevators, ships, packaging and other machinery, and when the power is off (risk prevention) braking and other occasions. Brakes that use electromagnetic effects to achieve braking are divided into electromagnetic powder brakes, electromagnetic eddy current brakes, electromagnetic friction brakes and other forms. ① Electromagnetic powder brakes: When the excitation coil is energized, a magnetic field is formed, and the magnetic powder is magnetized under the action of the magnetic field to form a magnetic powder chain, which is polymerized between the fixed magnetizer and the rotor, and braking is realized by the binding force and friction of the magnetic powder. When the exciting current disappears, the magnetic powder is in a free and loose state, and the braking effect is released. This kind of brake is small in size, light in weight, small in excitation power, and the braking torque has nothing to do with the speed of the rotating parts, but the magnetic powder will cause the parts to wear. It is convenient for automatic control and is suitable for the drive system of various machines. ② Electromagnetic eddy current brake: magnetic field is formed when the exciting coil is energized. The rotation of the armature on the brake shaft cuts the magnetic field lines and generates eddy currents. The eddy currents within the armature interact with the magnetic field to form a braking torque. The electromagnetic eddy current brake is durable, easy to maintain, and has a large speed range; but at low speed, the efficiency is low and the temperature rises, and heat dissipation measures must be taken. This type of brake is often used in machinery with vertical loads. ③Electromagnetic friction brake: The excitation coil is energized to generate a magnetic field, and the armature is attracted by the magnetic yoke, and the armature realizes shaft braking through the coupling flange. It is also subdivided into electromagnetic dry single-plate electromagnetic brake dry multi-plate electromagnetic brake wet multi-plate electromagnetic brake and so on. There are also braking methods that can be divided into power-on braking and power-off braking.

In order to ensure the uninterrupted operation of the electromagnetic brake, it must be maintained and maintained frequently: 1. Lubricant is often added to the movable part of the electromagnetic brake. 2. Regularly check the length of the armature stroke. This is because, during operation of the brake, the stroke length of the armature increases due to wear of the cross-sectional surface. When the armature stroke length does not reach the normal value, it must be adjusted to restore the minimum gap between the braking surface and the turntable. If the armature stroke length is increased above the normal value, the suction force may be greatly reduced. 3. If the worn braking surface is replaced, the minimum clearance between the braking surface and the turntable should be properly adjusted. 4. Always check the tightening degree of the bolts, especially tighten the bolts of the electromagnet, the bolts of the electromagnet and the housing, the bolts of the yoke, the bolts of the electromagnet coil and the terminal bolts. 5. Regularly check the mechanical wear of the movable parts, and remove the dust, flower hair and dirt on the surface of the electromagnet parts.

Product inquiry

The company has a product research and development department composed of experts, senior engineers and other professional and technical personnel. It is engaged in research and development and has perfect research and development test equipment. At present, the products reach more than 100 series of nearly 1,000 specifications, and the force distance ranges from 0.1N. m ~ 250000N.m. The company has been rated as a high-tech enterprise by the state for more than ten consecutive years, and a number of R & D projects have been established locally and have received municipal financial support.

Service Hotline:

Sales Department: Xu Jie

Sales Phone:+86-22-26616372, +86-22-26341260, +86 13920613215

Fax: 86-022-26616580

Market Development Department: Li Shuo

Marketing Department Telephone:+86-22-26614130

Technology Department: Yue Chao

Technical Department Telephone:+86-22-26222775 ,+86 18602228435

QQ:1059237223 1611412939

Company Website:www.tjlhq.com

Enterprise E-mail:xzm@tjlhq.com

Company address: No.6, Zone B, South Jifeng Road, Hongcang City Industrial Park, Yanji Daohong, Beichen District, Tianjin