Share

- Details

-

Electromagnetic clutch is also called electromagnetic coupling. It is an electromagnetic mechanical connector that applies the principle of electromagnetic induction and the friction between the inner and outer friction plates to make the two rotating parts in the mechanical transmission system. When the active part does not stop rotating, the driven part can be combined or separated with it., Is an automatic electrical appliance. The electromagnetic clutch can be used to control the starting, reverse, speed regulation and braking of the machine. It has the advantages of simple structure, fast action, low control energy, and easy remote control; although the volume is small, it can transmit a large torque; when used as a brake control, it has the advantages of rapid and stable braking, so the electromagnetic clutch is widely Used in various processing machine tools and mechanical transmission systems.

There are two types of electromagnetic clutches: fixed coil type and rotating coil type. The former electromagnetic coil is fixed on the compressor housing and does not rotate, while the latter electromagnetic coil is connected to the belt reel to rotate. (1) The fixed coil clutch electromagnetic coil is installed on the compressor end cover and does not rotate. The rotor is held on the electromagnetic coil by bearings and circlips. The outside of the rotor is the belt reel. The armature (clutch plate) is attached to the end of the compressor crankshaft. The fixed coil electromagnetic clutch is mainly composed of a pulley, an electromagnetic coil, a pressure plate, and a shaft hub assembly. One end of the electromagnetic coil is grounded, and the other end is connected to the power supply through an air conditioning relay. When the air conditioner switch is turned on, the air conditioning relay is turned on, and the electromagnetic coil of the compressor is energized, generating a strong magnetic field, so that the electromagnetic clutch driven disc of the compressor and the freely rotating pulley are attracted, thereby driving the compressor main shaft to rotate. The refrigeration system works. When the air conditioner relay is de-energized, the current of the electromagnetic clutch coil is cut off, and the magnetic field disappears. At this time, the driven plate and the pulley are separated by the action of the spring to stop the compressor. (2) The working principle of the rotating coil clutch is the same as that of the fixed coil clutch, but the position of the electromagnetic coil is different. In the rotating coil type structure, the electromagnetic coil is a part of the rotor and rotates with the rotor. An electric current flows through the brush mounted on the compressor to the electromagnetic coil to establish a magnetic field. The magnetic field brings the armature into contact with the rotor, and the rotation of the entire electromagnetic clutch device composed of the armature, rotor and coil drives the rotation of the compressor. These two types of electromagnetic clutches have several flow collecting grooves on the armature and the rotor to facilitate the collection of magnetic fields and increase the attraction of the two.

Main performance parameters

Main Technical DataSpecifications

ModelRated dynamic torque

Rated Torque

N.MRated static moment

Rated Static Torque

N.Mno-load moment

Drag Torque

(≦) N.mOn time

Engagement Time

(≦)SDisconnection time

Disengagement

(≦)SRated voltage

Rated Voltage

D.C.VCoil power consumption (20 ℃)

CoilPower(20℃)WMaximum allowable speed

Max Allowed Speed

r/minWeight

Weight

Kg10

100

110

1.00

0.25

0.05

24

36

2500

4.8

16

160

175

1.60

0.28

0.06

24

42

2000

6.2

40

400

440

4.00

0.35

0.12

24

43

1500

13.5

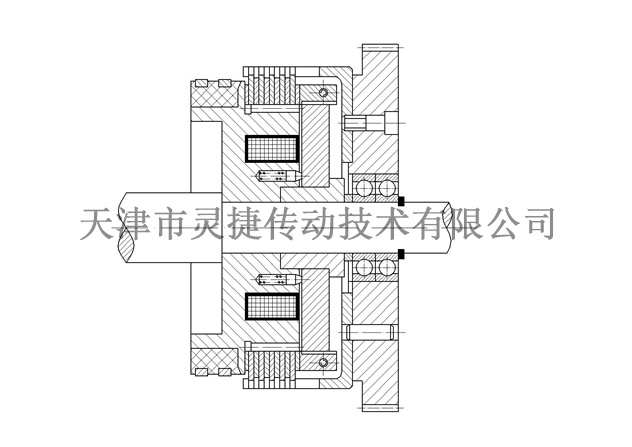

Installation Schematic

Installation Diagram

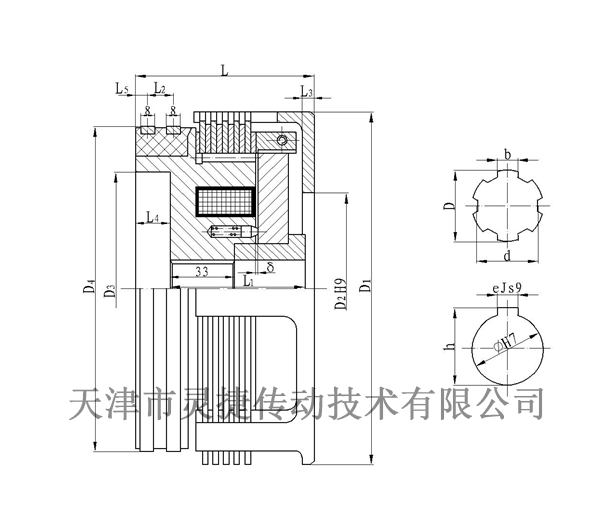

Outline and installation dimensions

Shape and Installation Dimensions

Specifications

ModelRadial Dimensions

Axial dimension Radial Dimensions

Brush model

Brush

ModelD1

D2

D3

D4

D

d

b

Φ

e

h

L

L1

L2

L3

L4

L5

Δ

10

128

80

80

122

350 0.027

300 0.14

10 0.035 0.085

35

10

37.80 0.1

77

57

13

8

14

7

0.360.05

DS-003

16

148

85

88

134

450 0.027

400 0.17

12 0.045 0.105

45

14

47.80 0.1

79

58

13

8

16

7

0.360.05

40

198

110

145

190

600 0.03

540 0.2

16 0.045 0.105

60

18

63.30 0.2

98

68

15

8

25

7

0.460.05

DLM2 series wet multi-disc electromagnetic clutch

Classification

Keyword

Multi-disc electromagnetic clutch

- Details

-

Electromagnetic clutch is also called electromagnetic coupling. It is an electromagnetic mechanical connector that applies the principle of electromagnetic induction and the friction between the inner and outer friction plates to make the two rotating parts in the mechanical transmission system. When the active part does not stop rotating, the driven part can be combined or separated with it., Is an automatic electrical appliance. The electromagnetic clutch can be used to control the starting, reverse, speed regulation and braking of the machine. It has the advantages of simple structure, fast action, low control energy, and easy remote control; although the volume is small, it can transmit a large torque; when used as a brake control, it has the advantages of rapid and stable braking, so the electromagnetic clutch is widely Used in various processing machine tools and mechanical transmission systems.

There are two types of electromagnetic clutches: fixed coil type and rotating coil type. The former electromagnetic coil is fixed on the compressor housing and does not rotate, while the latter electromagnetic coil is connected to the belt reel to rotate. (1) The fixed coil clutch electromagnetic coil is installed on the compressor end cover and does not rotate. The rotor is held on the electromagnetic coil by bearings and circlips. The outside of the rotor is the belt reel. The armature (clutch plate) is attached to the end of the compressor crankshaft. The fixed coil electromagnetic clutch is mainly composed of a pulley, an electromagnetic coil, a pressure plate, and a shaft hub assembly. One end of the electromagnetic coil is grounded, and the other end is connected to the power supply through an air conditioning relay. When the air conditioner switch is turned on, the air conditioning relay is turned on, and the electromagnetic coil of the compressor is energized, generating a strong magnetic field, so that the electromagnetic clutch driven disc of the compressor and the freely rotating pulley are attracted, thereby driving the compressor main shaft to rotate. The refrigeration system works. When the air conditioner relay is de-energized, the current of the electromagnetic clutch coil is cut off, and the magnetic field disappears. At this time, the driven plate and the pulley are separated by the action of the spring to stop the compressor. (2) The working principle of the rotating coil clutch is the same as that of the fixed coil clutch, but the position of the electromagnetic coil is different. In the rotating coil type structure, the electromagnetic coil is a part of the rotor and rotates with the rotor. An electric current flows through the brush mounted on the compressor to the electromagnetic coil to establish a magnetic field. The magnetic field brings the armature into contact with the rotor, and the rotation of the entire electromagnetic clutch device composed of the armature, rotor and coil drives the rotation of the compressor. These two types of electromagnetic clutches have several flow collecting grooves on the armature and the rotor to facilitate the collection of magnetic fields and increase the attraction of the two.

Main performance parameters

Main Technical DataSpecifications

ModelRated dynamic torque

Rated Torque

N.MRated static moment

Rated Static Torque

N.Mno-load moment

Drag Torque

(≦) N.mOn time

Engagement Time

(≦)SDisconnection time

Disengagement

(≦)SRated voltage

Rated Voltage

D.C.VCoil power consumption (20 ℃)

CoilPower(20℃)WMaximum allowable speed

Max Allowed Speed

r/minWeight

Weight

Kg10

100

110

1.00

0.25

0.05

24

36

2500

4.8

16

160

175

1.60

0.28

0.06

24

42

2000

6.2

40

400

440

4.00

0.35

0.12

24

43

1500

13.5

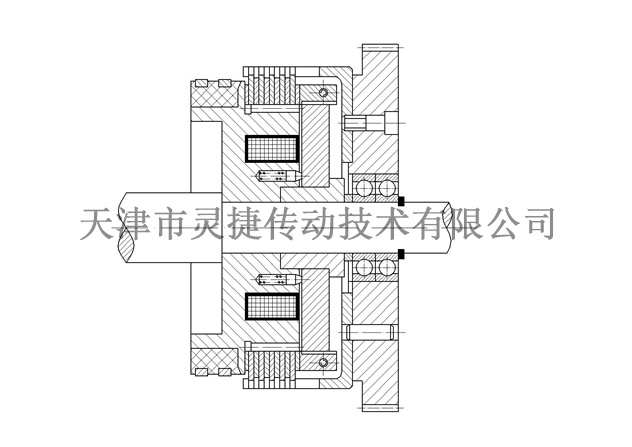

Installation Schematic

Installation Diagram

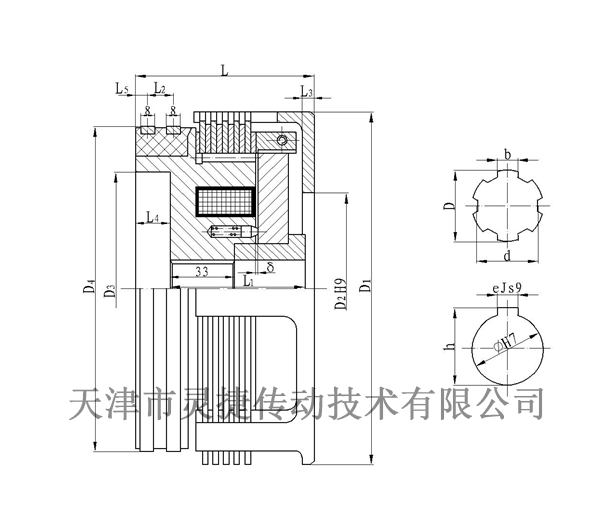

Outline and installation dimensions

Shape and Installation Dimensions

Specifications

ModelRadial Dimensions

Axial dimension Radial Dimensions

Brush model

Brush

ModelD1

D2

D3

D4

D

d

b

Φ

e

h

L

L1

L2

L3

L4

L5

Δ

10

128

80

80

122

350 0.027

300 0.14

10 0.035 0.085

35

10

37.80 0.1

77

57

13

8

14

7

0.360.05

DS-003

16

148

85

88

134

450 0.027

400 0.17

12 0.045 0.105

45

14

47.80 0.1

79

58

13

8

16

7

0.360.05

40

198

110

145

190

600 0.03

540 0.2

16 0.045 0.105

60

18

63.30 0.2

98

68

15

8

25

7

0.460.05

Product inquiry

The company has a product research and development department composed of experts, senior engineers and other professional and technical personnel. It is engaged in research and development and has perfect research and development test equipment. At present, the products reach more than 100 series of nearly 1,000 specifications, and the force distance ranges from 0.1N. m ~ 250000N.m. The company has been rated as a high-tech enterprise by the state for more than ten consecutive years, and a number of R & D projects have been established locally and have received municipal financial support.

Service Hotline:

Sales Department: Xu Jie

Sales Phone:+86-22-26616372, +86-22-26341260, +86 13920613215

Fax: 86-022-26616580

Market Development Department: Li Shuo

Marketing Department Telephone:+86-22-26614130

Technology Department: Yue Chao

Technical Department Telephone:+86-22-26222775 ,+86 18602228435

QQ:1059237223 1611412939

Company Website:www.tjlhq.com

Enterprise E-mail:xzm@tjlhq.com

Company address: No.6, Zone B, South Jifeng Road, Hongcang City Industrial Park, Yanji Daohong, Beichen District, Tianjin