Share

- Details

-

The jaw-type electromagnetic clutch is composed of two half-clutches with teeth on the end faces. Half of the clutches are fixedly connected to the driving shaft, and the other half-clutch I is connected to the driven shaft with a guide key (or spline).

The clutch I can be moved axially along the guide key through the operating mechanism, and the two shafts are connected by the teeth on the end faces of the two clutch halves. In order to center the two shafts, a centering ring is fixed to the half clutch 1, and the driven shaft can rotate in the centering ring itself.

Jaw-type electromagnetic clutch commonly used in triangular, rectangular, trapezoidal, sawtooth, etc., its radial section as shown in the figure. The triangular teeth of the jaw-mounted electromagnetic clutch are mostly used in light load situations, which are easy to engage and component forces, but the strength of the teeth is low. Rectangular teeth are not easy to connect and difficult to separate, and are only used for manual engagement when stationary.

The side of the trapezoidal tooth is made into an oblique angle of a = 20~8 °, the root strength is higher, the torque can be transmitted larger, and the tooth side clearance caused by wear can be compensated, and the engagement and separation are relatively easy, so the trapezoidal tooth is widely used.

Triangular, rectangular, trapezoidal teeth can be used for two-way work, and serrated teeth can only work in one direction, but its root strength is very high, the transmission torque capacity is large, and it is mostly used under heavy load.

Main performance parameters

Main Technical DataSpecifications

ModelRated transmission torque

Rated Transmitting Torque (N.m)Rated voltage

Rated Voltage

D.C(V)Coil power consumption (20 ℃)

Coil power(20℃)

WMaximum allowable speed

Max Allowed Speed(r/min)5A

50

24

24

50

25A

250

24

38

20

41A

410

24

64

15

63A

630

24

60

Relatively stationary

100A

1000

24

80

Relatively stationary

200A

2200

24

110

Relatively stationary

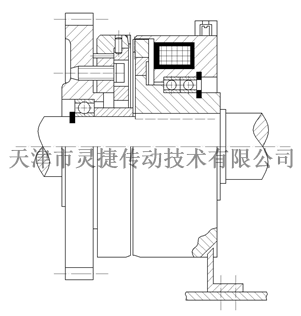

Installation Schematic

Installation Diagram

Specifications

ModelRadial Dimensions

Axial Dimensions

D1

D2

D3

D4

D5

D6

D7

φ1

φ2

Φ

h

e

L

L1

L2

L3

a

Δ

5A

82

58

42

36

35

75

82

3-φ4.5

3-φ10

20

22.80 0.1

6

55

42

6

8

45°

0.3±0.05

25A

115

80

62

55

55

105

115

3-φ6.5

3-φ12

40

43.30 0.2

12

70

50.8

5

10

45°

0.4±0.1

41A

134

95

72

68

70

127

134

6-φ8.5

6-φ15

45

48.80 0.2

14

83

61

7

10

45°

0.4±0.1

63A

145

95

72

65

65

127

145

3-φ8.5

3-φ15

40

43.30 0.2

12

85.6

64.5

5

10

45°

0.7±0.1

100A

166

120

90

80

85

152

166

6-φ8.5

6-φ14.5

60

64.40 0.2

18

95

68

10

12

45°

0.7±0.1

200A

210

160

130

95

105

190

210

6-φ10.5

6-φ18

85

90.40 0.2

22

110

80

10

12

45°

0.4±0.05

DLY3 series jaw electromagnetic clutch

Classification

Keyword

Jaw electromagnetic clutch

- Details

-

The jaw-type electromagnetic clutch is composed of two half-clutches with teeth on the end faces. Half of the clutches are fixedly connected to the driving shaft, and the other half-clutch I is connected to the driven shaft with a guide key (or spline).

The clutch I can be moved axially along the guide key through the operating mechanism, and the two shafts are connected by the teeth on the end faces of the two clutch halves. In order to center the two shafts, a centering ring is fixed to the half clutch 1, and the driven shaft can rotate in the centering ring itself.

Jaw-type electromagnetic clutch commonly used in triangular, rectangular, trapezoidal, sawtooth, etc., its radial section as shown in the figure. The triangular teeth of the jaw-mounted electromagnetic clutch are mostly used in light load situations, which are easy to engage and component forces, but the strength of the teeth is low. Rectangular teeth are not easy to connect and difficult to separate, and are only used for manual engagement when stationary.

The side of the trapezoidal tooth is made into an oblique angle of a = 20~8 °, the root strength is higher, the torque can be transmitted larger, and the tooth side clearance caused by wear can be compensated, and the engagement and separation are relatively easy, so the trapezoidal tooth is widely used.

Triangular, rectangular, trapezoidal teeth can be used for two-way work, and serrated teeth can only work in one direction, but its root strength is very high, the transmission torque capacity is large, and it is mostly used under heavy load.

Main performance parameters

Main Technical DataSpecifications

ModelRated transmission torque

Rated Transmitting Torque (N.m)Rated voltage

Rated Voltage

D.C(V)Coil power consumption (20 ℃)

Coil power(20℃)

WMaximum allowable speed

Max Allowed Speed(r/min)5A

50

24

24

50

25A

250

24

38

20

41A

410

24

64

15

63A

630

24

60

Relatively stationary

100A

1000

24

80

Relatively stationary

200A

2200

24

110

Relatively stationary

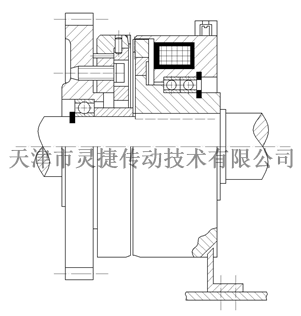

Installation Schematic

Installation Diagram

Specifications

ModelRadial Dimensions

Axial Dimensions

D1

D2

D3

D4

D5

D6

D7

φ1

φ2

Φ

h

e

L

L1

L2

L3

a

Δ

5A

82

58

42

36

35

75

82

3-φ4.5

3-φ10

20

22.80 0.1

6

55

42

6

8

45°

0.3±0.05

25A

115

80

62

55

55

105

115

3-φ6.5

3-φ12

40

43.30 0.2

12

70

50.8

5

10

45°

0.4±0.1

41A

134

95

72

68

70

127

134

6-φ8.5

6-φ15

45

48.80 0.2

14

83

61

7

10

45°

0.4±0.1

63A

145

95

72

65

65

127

145

3-φ8.5

3-φ15

40

43.30 0.2

12

85.6

64.5

5

10

45°

0.7±0.1

100A

166

120

90

80

85

152

166

6-φ8.5

6-φ14.5

60

64.40 0.2

18

95

68

10

12

45°

0.7±0.1

200A

210

160

130

95

105

190

210

6-φ10.5

6-φ18

85

90.40 0.2

22

110

80

10

12

45°

0.4±0.05

Product inquiry

The company has a product research and development department composed of experts, senior engineers and other professional and technical personnel. It is engaged in research and development and has perfect research and development test equipment. At present, the products reach more than 100 series of nearly 1,000 specifications, and the force distance ranges from 0.1N. m ~ 250000N.m. The company has been rated as a high-tech enterprise by the state for more than ten consecutive years, and a number of R & D projects have been established locally and have received municipal financial support.

Service Hotline:

Sales Department: Xu Jie

Sales Phone:+86-22-26616372, +86-22-26341260, +86 13920613215

Fax: 86-022-26616580

Market Development Department: Li Shuo

Marketing Department Telephone:+86-22-26614130

Technology Department: Yue Chao

Technical Department Telephone:+86-22-26222775 ,+86 18602228435

QQ:1059237223 1611412939

Company Website:www.tjlhq.com

Enterprise E-mail:xzm@tjlhq.com

Company address: No.6, Zone B, South Jifeng Road, Hongcang City Industrial Park, Yanji Daohong, Beichen District, Tianjin