Share

- Details

-

1) Since the engagement and disengagement of the electromagnetic clutch are carried out at high speed, there will be many traces of clutch on the iron suction plate and the surface of the rotor. These marks are not hazardous to work and are permitted. 2) Apply a suitable voltage to the electromagnetic coil. For a 12V voltage electromagnetic coil, if it is added to a 6V voltage system, it cannot generate enough magnetic field, which will cause the suction iron to slip, shorten the life of the clutch, and reduce the cooling capacity. Conversely, if a 6V coil is added to a 12V voltage system, the coil life will be shortened. 3) The gap between the coil and the rotor is very important. The coil and the rotor should be as close as possible to obtain a stronger magnetic field, but the gap should not be too small to prevent the rotor from dragging the coil (for the fixed-ring clutch). 4) The gap between the rotor and the suction iron is also very important. If this gap is too small, the rotor will drag the suction iron when the clutch is disengaged. However, if the gap is too large, there is too little contact between them when the clutch is operated. Both of these conditions can cause poor clutch performance. The reasonable gap between them should be that when the clutch has no current, the two do not drag; when the clutch has current, it can ensure that no slippage occurs.

1. Connection and cut-off action: installation between the driving part and the starting part does not need to stop the driving part, and the starting part will do connection and cut-off action according to the necessary reaction. 2. Speed change: there is a situation of mutual speed change during the operation. If the clutch is used at this time, the speed can be changed without closing the drive. 3. Positive and reverse rotation: When the load point is switched to positive and reverse rotation, it is only necessary to rotate in the forward direction when used with the clutch. 4. High-frequency operation: in the rapid cycle of intermittent operation, repeated use of the motor ON, OFF provided by the frequency is limited, so the use of clutch, so that rapid response, high-precision braking. 5. Inching: When the machine starts to operate and the position is engaged, it only needs to operate the clutch instantaneously.

Main performance parameters

Main Technical Data

Specifications

ModelRated dynamic torque

Rated Torque

N.MRated static moment

Rated Static Torque

N.Mno-load moment

Drag Torque

(≦) N.mOn time Engagement Time

(≦)SDisconnection time

Disengagement

(≦)SRated voltage

Rated Voltage

D.C.VCoil power consumption (20 ℃)

CoilPower

(20℃)WMaximum allowable speed

Max Allowed Speed

r/minWeight

Weight

KgOil supply flow

Oil Flow Rates

L/min1.2/1.2C

12

20

0.39

0.28

0.09

24

10

3500

1.3

0.20

2.5

25

40

0.40

0.30

0.09

24

17

3500

1.73

0.25

5/5C

50

80

0.9

0.32

0.10

24

17

3000

2.9

0.40

10/10C

100

160

1.80

0.35

0.14

24

19

3000

4.3

0.65

16

160

250

2.40

0.37

0.14

24

26

2500

5.53

0.65

25/25C

250

400

3.50

0.40

0.18

24

39

2200

8

1.00

40

400

630

5.60

0.42

0.20

24

45

2000

12.2

1.00

63

630

1000

9.00

0.45

0.25

24

66

1800

16.2

1.2

100

1000

1600

15.0

0.65

0.35

24

81

1600

23.2

1.2

160

1600

2500

24.0

0.90

0.45

24

87

1600

31.7

1.5

250

2500

4000

37.50

1.20

0.60

24

100

1200

47.1

2.0

400

4000

63000

60.00

1.50

0.80

24

134

1000

100.9

3.0

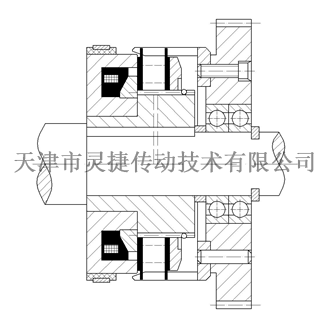

Installation Schematic

Installation Diagram

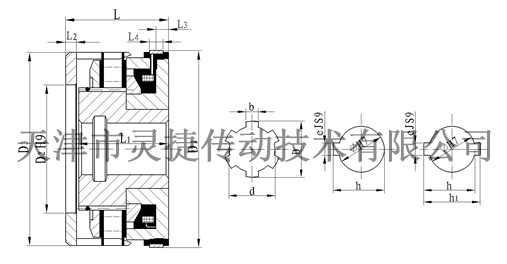

Outline and installation dimensions

Shape and Installation Dimensions

Specifications

ModelRadial Dimensions

Axial dimension Radial Dimensions

Brush model

D1

D2

D3

D

d

b

Φ

e

h

H1

L

L1

L2

L3

L4

DS-002

1.2

86

50

86

200 0.023

170 0.12

6 0.025 0.065

20

6

22.80 0.1

——

43.5

38

5.5

5

7

2.5

96

56

96

250 0.023

210 0.14

5 0.025 0.065

25

8

28.30 0.2

——

48.5

43

5.5

7

7

5

113

65

113

300 0.023

260 0.14

6 0.025 0.065

30

8

33.30 0.2

——

55.5

50

5.5

7

8

DS-001

10

133

75

133

400 0.027

350 0.17

10 0.035 0.085

40

12

43.30 0.2

——

61

54.5

6.5

8

10

16

145

85

145

450 0.027

400 0.17

12 0.045 0.105

45

14

48.80 0.2

——

63.5

57

6.5

8

10

25

166

95

166

500 0.027

450 0.17

12 0.045 0.105

50

14

53.80 0.2

——

72

64.5

7.5

10

10

40

192

120

192

600 0.030

540 0.20

14 0.045 0.105

60

18

64.40 0.2

——

82.5

74.5

8

10

10

63

212

125

212

700 0.030

620 0.20

16 0.045 0.105

70

20

74.90 0.2

——

91.5

82

9.5

12

10

100

235

150

235

——

——

——

70

20

74.90 0.2

——

105

96

10

15

10

160

270

180

270

——

——

——

100

28

106.40 0.2

——

118

104

14

15

10

250

310

220

310

——

——

——

110

28

116.40 0.2

122.80 0.4

130

116

14

10

12

400

415

235

415

——

——

——

120

32

127.40 0.2

134.80 0.4

150

132

18

10

12

1.2C

94

50

86

300 0.023

260 0.14

8 0.035 0.085

——

——

——

——

56

50.5

5.5

19

10

5C

116

65

113

400 0.027

350 0.17

10 0.035 0.023

——

——

——

——

59.5

54

5.5

19

10

10C

142

85

133

500 0.027

450 0.17

12 0.045 0.105

——

——

——

——

64.5

58

6.5

19

10

25C

176

105

166

650 0.030

580 0.20

16 0.045 0.105

——

——

——

——

81

73.5

7.5

21

10

DLM5 Series Wet Multi-disc Electromagnetic Clutch

Classification

Keyword

Multi-disc electromagnetic clutch

- Details

-

1) Since the engagement and disengagement of the electromagnetic clutch are carried out at high speed, there will be many traces of clutch on the iron suction plate and the surface of the rotor. These marks are not hazardous to work and are permitted. 2) Apply a suitable voltage to the electromagnetic coil. For a 12V voltage electromagnetic coil, if it is added to a 6V voltage system, it cannot generate enough magnetic field, which will cause the suction iron to slip, shorten the life of the clutch, and reduce the cooling capacity. Conversely, if a 6V coil is added to a 12V voltage system, the coil life will be shortened. 3) The gap between the coil and the rotor is very important. The coil and the rotor should be as close as possible to obtain a stronger magnetic field, but the gap should not be too small to prevent the rotor from dragging the coil (for the fixed-ring clutch). 4) The gap between the rotor and the suction iron is also very important. If this gap is too small, the rotor will drag the suction iron when the clutch is disengaged. However, if the gap is too large, there is too little contact between them when the clutch is operated. Both of these conditions can cause poor clutch performance. The reasonable gap between them should be that when the clutch has no current, the two do not drag; when the clutch has current, it can ensure that no slippage occurs.

1. Connection and cut-off action: installation between the driving part and the starting part does not need to stop the driving part, and the starting part will do connection and cut-off action according to the necessary reaction. 2. Speed change: there is a situation of mutual speed change during the operation. If the clutch is used at this time, the speed can be changed without closing the drive. 3. Positive and reverse rotation: When the load point is switched to positive and reverse rotation, it is only necessary to rotate in the forward direction when used with the clutch. 4. High-frequency operation: in the rapid cycle of intermittent operation, repeated use of the motor ON, OFF provided by the frequency is limited, so the use of clutch, so that rapid response, high-precision braking. 5. Inching: When the machine starts to operate and the position is engaged, it only needs to operate the clutch instantaneously.

Main performance parameters

Main Technical Data

Specifications

ModelRated dynamic torque

Rated Torque

N.MRated static moment

Rated Static Torque

N.Mno-load moment

Drag Torque

(≦) N.mOn time Engagement Time

(≦)SDisconnection time

Disengagement

(≦)SRated voltage

Rated Voltage

D.C.VCoil power consumption (20 ℃)

CoilPower

(20℃)WMaximum allowable speed

Max Allowed Speed

r/minWeight

Weight

KgOil supply flow

Oil Flow Rates

L/min1.2/1.2C

12

20

0.39

0.28

0.09

24

10

3500

1.3

0.20

2.5

25

40

0.40

0.30

0.09

24

17

3500

1.73

0.25

5/5C

50

80

0.9

0.32

0.10

24

17

3000

2.9

0.40

10/10C

100

160

1.80

0.35

0.14

24

19

3000

4.3

0.65

16

160

250

2.40

0.37

0.14

24

26

2500

5.53

0.65

25/25C

250

400

3.50

0.40

0.18

24

39

2200

8

1.00

40

400

630

5.60

0.42

0.20

24

45

2000

12.2

1.00

63

630

1000

9.00

0.45

0.25

24

66

1800

16.2

1.2

100

1000

1600

15.0

0.65

0.35

24

81

1600

23.2

1.2

160

1600

2500

24.0

0.90

0.45

24

87

1600

31.7

1.5

250

2500

4000

37.50

1.20

0.60

24

100

1200

47.1

2.0

400

4000

63000

60.00

1.50

0.80

24

134

1000

100.9

3.0

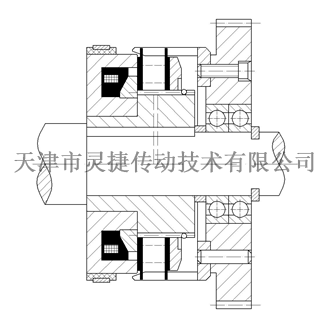

Installation Schematic

Installation Diagram

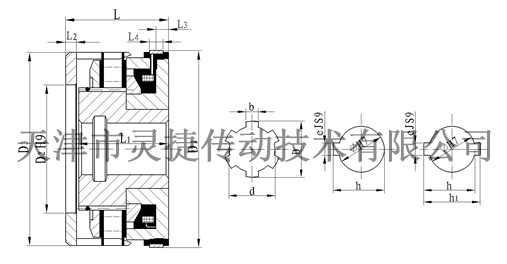

Outline and installation dimensions

Shape and Installation Dimensions

Specifications

ModelRadial Dimensions

Axial dimension Radial Dimensions

Brush model

D1

D2

D3

D

d

b

Φ

e

h

H1

L

L1

L2

L3

L4

DS-002

1.2

86

50

86

200 0.023

170 0.12

6 0.025 0.065

20

6

22.80 0.1

——

43.5

38

5.5

5

7

2.5

96

56

96

250 0.023

210 0.14

5 0.025 0.065

25

8

28.30 0.2

——

48.5

43

5.5

7

7

5

113

65

113

300 0.023

260 0.14

6 0.025 0.065

30

8

33.30 0.2

——

55.5

50

5.5

7

8

DS-001

10

133

75

133

400 0.027

350 0.17

10 0.035 0.085

40

12

43.30 0.2

——

61

54.5

6.5

8

10

16

145

85

145

450 0.027

400 0.17

12 0.045 0.105

45

14

48.80 0.2

——

63.5

57

6.5

8

10

25

166

95

166

500 0.027

450 0.17

12 0.045 0.105

50

14

53.80 0.2

——

72

64.5

7.5

10

10

40

192

120

192

600 0.030

540 0.20

14 0.045 0.105

60

18

64.40 0.2

——

82.5

74.5

8

10

10

63

212

125

212

700 0.030

620 0.20

16 0.045 0.105

70

20

74.90 0.2

——

91.5

82

9.5

12

10

100

235

150

235

——

——

——

70

20

74.90 0.2

——

105

96

10

15

10

160

270

180

270

——

——

——

100

28

106.40 0.2

——

118

104

14

15

10

250

310

220

310

——

——

——

110

28

116.40 0.2

122.80 0.4

130

116

14

10

12

400

415

235

415

——

——

——

120

32

127.40 0.2

134.80 0.4

150

132

18

10

12

1.2C

94

50

86

300 0.023

260 0.14

8 0.035 0.085

——

——

——

——

56

50.5

5.5

19

10

5C

116

65

113

400 0.027

350 0.17

10 0.035 0.023

——

——

——

——

59.5

54

5.5

19

10

10C

142

85

133

500 0.027

450 0.17

12 0.045 0.105

——

——

——

——

64.5

58

6.5

19

10

25C

176

105

166

650 0.030

580 0.20

16 0.045 0.105

——

——

——

——

81

73.5

7.5

21

10

Product inquiry

The company has a product research and development department composed of experts, senior engineers and other professional and technical personnel. It is engaged in research and development and has perfect research and development test equipment. At present, the products reach more than 100 series of nearly 1,000 specifications, and the force distance ranges from 0.1N. m ~ 250000N.m. The company has been rated as a high-tech enterprise by the state for more than ten consecutive years, and a number of R & D projects have been established locally and have received municipal financial support.

Service Hotline:

Sales Department: Xu Jie

Sales Phone:+86-22-26616372, +86-22-26341260, +86 13920613215

Fax: 86-022-26616580

Market Development Department: Li Shuo

Marketing Department Telephone:+86-22-26614130

Technology Department: Yue Chao

Technical Department Telephone:+86-22-26222775 ,+86 18602228435

QQ:1059237223 1611412939

Company Website:www.tjlhq.com

Enterprise E-mail:xzm@tjlhq.com

Company address: No.6, Zone B, South Jifeng Road, Hongcang City Industrial Park, Yanji Daohong, Beichen District, Tianjin