Share

- Details

-

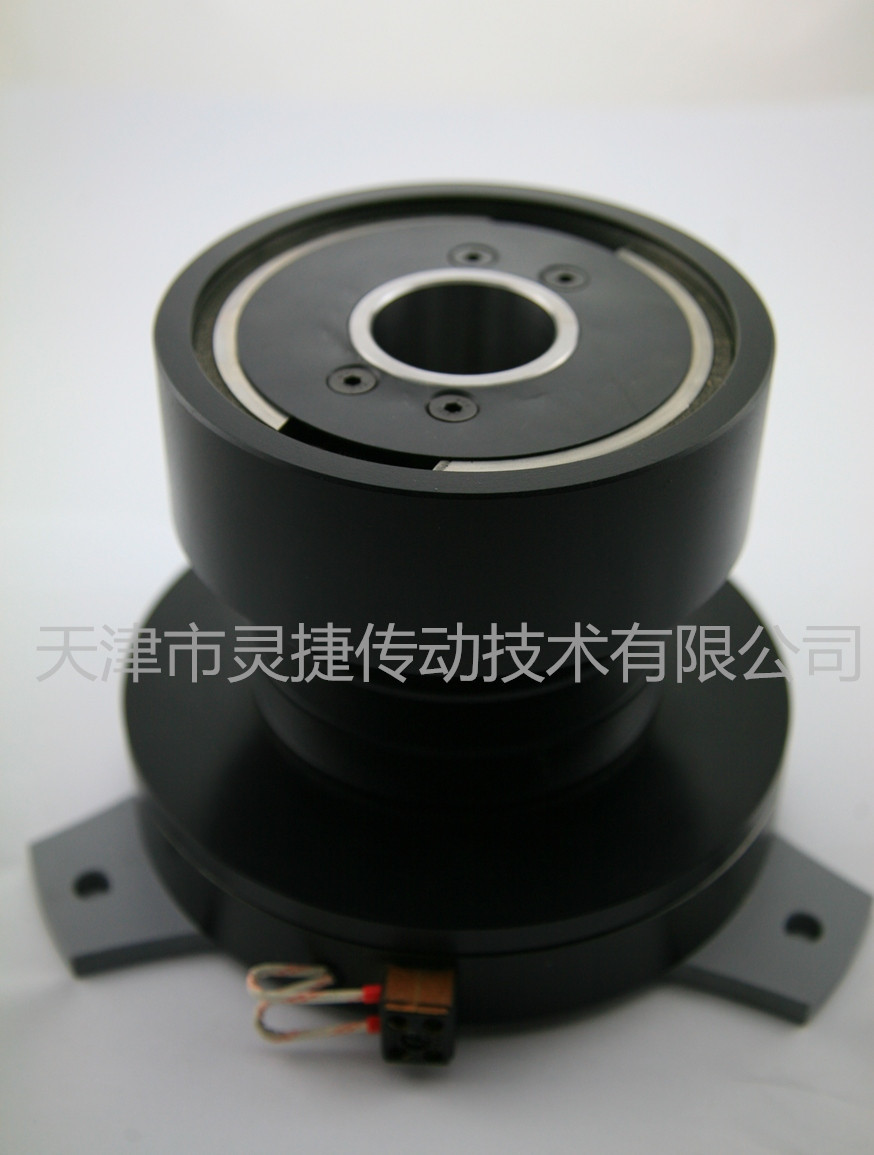

The electromagnetic brake is a connector that transmits the torque of the active side to the passive side. It can be freely combined, cut or braked as needed. It has compact structure, simple operation, sensitive response, long life, reliable use, and easy to realize long distance Control and other advantages.

Electromagnetic brake is a very important part of elevator, stage, ship, metallurgy, lifting machinery and other machines. However, in the existing mechanical equipment, there are few real-time detection of the braking force and the braking process, and only manual maintenance and adjustment are carried out regularly. Therefore, the wear of the friction pair, the fatigue of the brake spring, and the large voltage during the use of the brake. Occasional failures such as fluctuations cannot be detected and prevented in time. The working environment of the electromagnetic brake is complex, the brake components are easily damaged, and some faults such as slow brake action and disordered action often occur, which are usually caused by mechanical and electrical faults. Common mechanical failure phenomena include insufficient braking force, failure of the brake arm to open, slow brake release, although the brake spring is tightened and the braking torque is also increased, but it still cannot be braked in time, the brake suddenly fails, and the brake wheel The temperature is too high, the brake shoe smokes, and the brake fails. The electromagnetic brake itself still has some problems, such as: the release and closing time of the electromagnetic brake is short, the power impact when closing is large, and it is not stable enough; as an electrical equipment, whether it is AC or DC power supply, it must be controlled by a special power supply. When the power supply voltage fluctuates greatly, its control and maintenance are relatively complicated, and it is not easy to control it; the electromagnetic brake mainly realizes braking through the movement of the armature. Therefore, the size of the air gap of the armature is relatively high, but its air gap is very small, less than 1mm. If there is improper operation, it will easily lead to operational failure and cause the reliability of the brake. Poor, unstable operation.

1. main purpose:

The centrifugal electromagnetic brake 15704 is mainly used for braking the two-speed main motor of Dalian CKA6150 CNC machine tools.

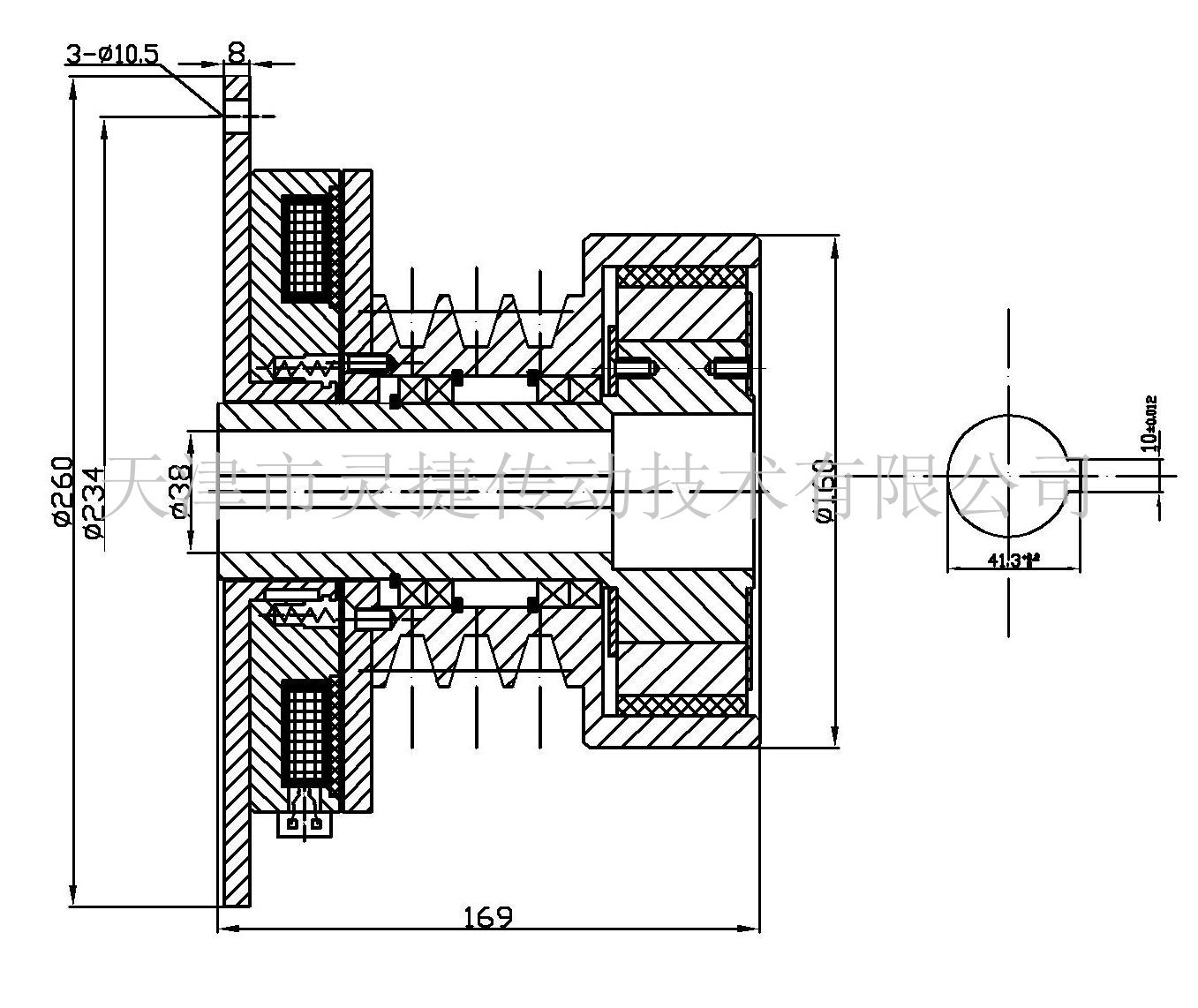

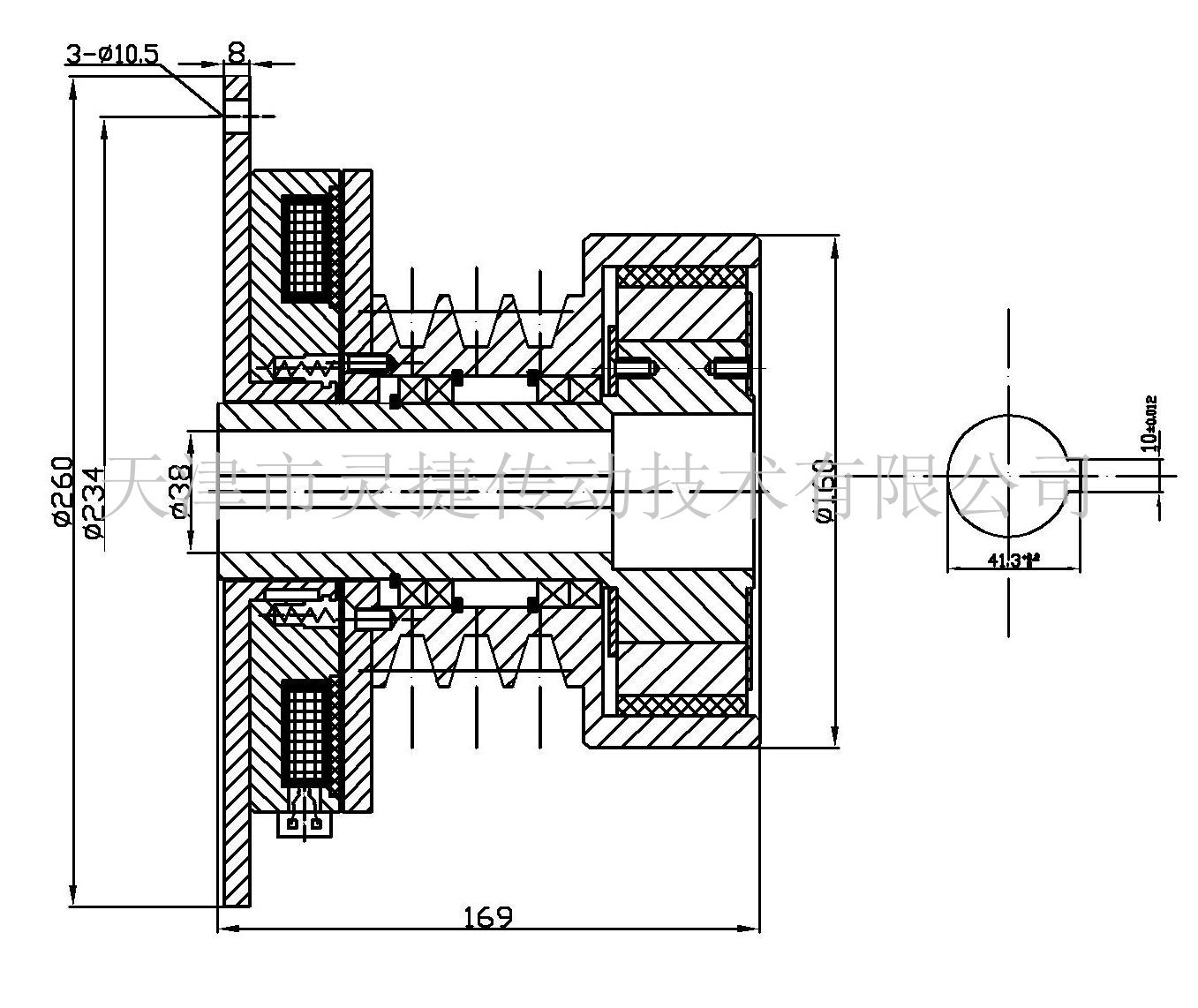

Main performance parameters and dimensions of 2.

Model

Voltage (V)

Torque (Nm)

Outer diameter (mm)

Height (mm)

Shaft hole (mm)

15704

DC 24V

160

260

169

38

Dalian CNC Machine Tool CKA6150 Centrifugal Electromagnetic Brake 15704

Classification

Keyword

Centrifugal electromagnetic brake

- Details

-

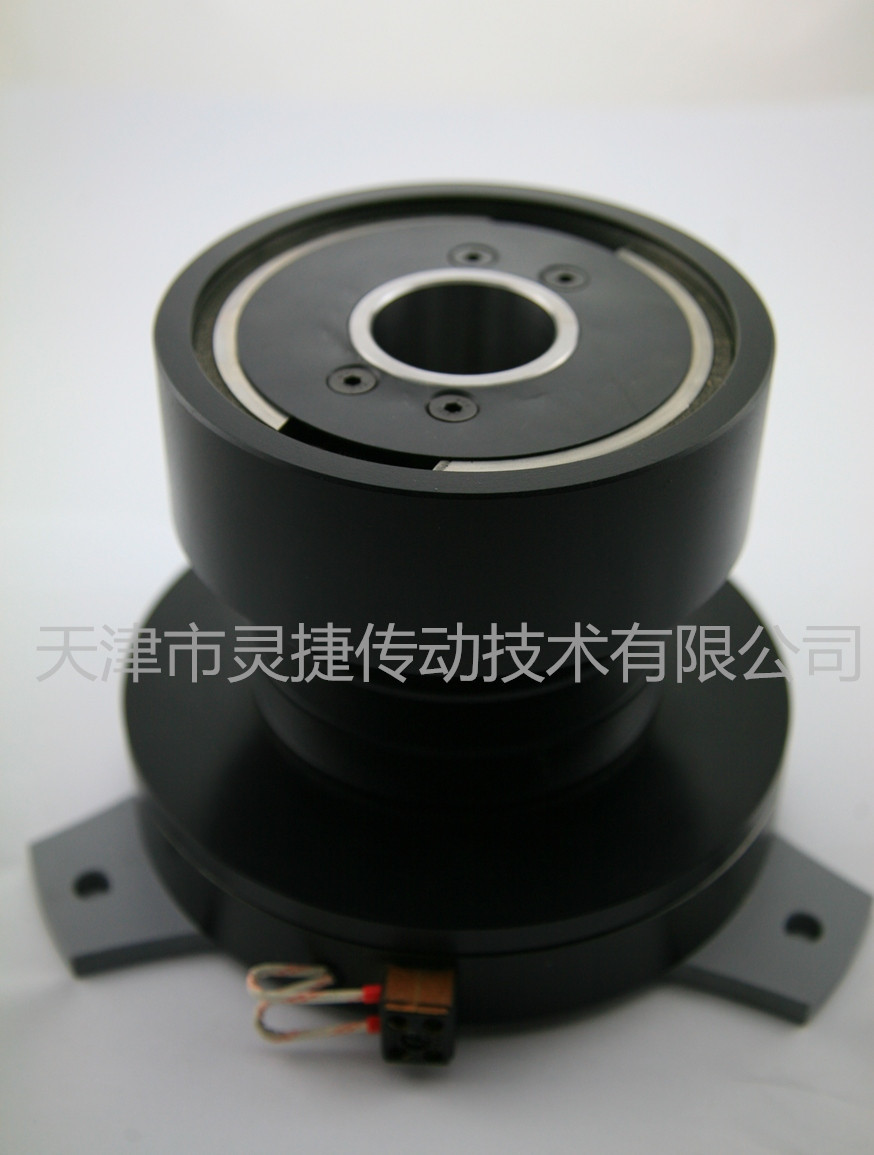

The electromagnetic brake is a connector that transmits the torque of the active side to the passive side. It can be freely combined, cut or braked as needed. It has compact structure, simple operation, sensitive response, long life, reliable use, and easy to realize long distance Control and other advantages.

Electromagnetic brake is a very important part of elevator, stage, ship, metallurgy, lifting machinery and other machines. However, in the existing mechanical equipment, there are few real-time detection of the braking force and the braking process, and only manual maintenance and adjustment are carried out regularly. Therefore, the wear of the friction pair, the fatigue of the brake spring, and the large voltage during the use of the brake. Occasional failures such as fluctuations cannot be detected and prevented in time. The working environment of the electromagnetic brake is complex, the brake components are easily damaged, and some faults such as slow brake action and disordered action often occur, which are usually caused by mechanical and electrical faults. Common mechanical failure phenomena include insufficient braking force, failure of the brake arm to open, slow brake release, although the brake spring is tightened and the braking torque is also increased, but it still cannot be braked in time, the brake suddenly fails, and the brake wheel The temperature is too high, the brake shoe smokes, and the brake fails. The electromagnetic brake itself still has some problems, such as: the release and closing time of the electromagnetic brake is short, the power impact when closing is large, and it is not stable enough; as an electrical equipment, whether it is AC or DC power supply, it must be controlled by a special power supply. When the power supply voltage fluctuates greatly, its control and maintenance are relatively complicated, and it is not easy to control it; the electromagnetic brake mainly realizes braking through the movement of the armature. Therefore, the size of the air gap of the armature is relatively high, but its air gap is very small, less than 1mm. If there is improper operation, it will easily lead to operational failure and cause the reliability of the brake. Poor, unstable operation.

1. main purpose:

The centrifugal electromagnetic brake 15704 is mainly used for braking the two-speed main motor of Dalian CKA6150 CNC machine tools.

Main performance parameters and dimensions of 2.

Model

Voltage (V)

Torque (Nm)

Outer diameter (mm)

Height (mm)

Shaft hole (mm)

15704

DC 24V

160

260

169

38

Product inquiry

The company has a product research and development department composed of experts, senior engineers and other professional and technical personnel. It is engaged in research and development and has perfect research and development test equipment. At present, the products reach more than 100 series of nearly 1,000 specifications, and the force distance ranges from 0.1N. m ~ 250000N.m. The company has been rated as a high-tech enterprise by the state for more than ten consecutive years, and a number of R & D projects have been established locally and have received municipal financial support.

Service Hotline:

Sales Department: Xu Jie

Sales Phone:+86-22-26616372, +86-22-26341260, +86 13920613215

Fax: 86-022-26616580

Market Development Department: Li Shuo

Marketing Department Telephone:+86-22-26614130

Technology Department: Yue Chao

Technical Department Telephone:+86-22-26222775 ,+86 18602228435

QQ:1059237223 1611412939

Company Website:www.tjlhq.com

Enterprise E-mail:xzm@tjlhq.com

Company address: No.6, Zone B, South Jifeng Road, Hongcang City Industrial Park, Yanji Daohong, Beichen District, Tianjin