Share

- Details

-

The single-plate electromagnetic clutch is a dry type electromagnetic clutch. If the installation, adjustment and maintenance are not in place, it is easy to cause the service life and working performance of the single-plate electromagnetic clutch to decrease.The common abnormalities of single-chip electromagnetic clutches are slipping or short life, which will affect normal operation. Most single-chip electromagnetic clutch users do not pay attention to the single-chip electromagnetic clutch working surface, cleaning work, the above-mentioned circumferential abnormal failure, one of the reasons for the use of the environment.

There are a lot of dust, water, oil, etc. in the use environment of single-chip electromagnetic clutches. These factors directly affect the service life and working performance of the entire electromagnetic clutch.

Therefore, the user must do a good job in daily maintenance, and cannot contact any water, oil, dust, etc. between and around the working single-piece electromagnetic clutch. The electromagnetic clutch coil controls the engagement and disengagement of the clutch.

Electromagnetic clutches are divided into: dry single-plate electromagnetic clutches, dry multi-plate electromagnetic clutches, wet multi-plate electromagnetic clutches, magnetic powder clutches, slip-type electromagnetic clutches, etc. The working principle of electromagnetic clutch can be divided into: power on and power off.

Dry single-plate electromagnetic clutch, when the coil generates electromagnetic force and the armature, the clutch is in the engaged state; when the clutch is in the disengaged state, the coil power supply is "armored".

Dry multi-disc wet multi-disc electromagnetic clutch: On the basis of the above principle, plus some other friction, the torque of the same volume is better than that of dry single-disc electromagnetic clutch. The wet multi-disc electromagnetic clutch must have oil cooling and lubrication. Magnetic powder clutch: magnetic powder is placed between the driving and driven parts. The magnetic powder in the loose state is not charged, and the electricity combines the magnetic powder with the driving part and the driven part to rotate at the same time.

Main performance parameters

Main Technical DataModel

ModelRated dynamic torque

Rated Torque

(N.M)static moment

Rated Static Torque

(N.M)Rated voltage

Rated Voltage

D.C(V)Coil power consumption (20 ℃)

Coil power(20℃) WMaximum allowable speed

Max Allowed Speed(r/min)Clutch

ClutchBrake

Brake0.4

4

4.4

24

-

12

4000

1

10

11

24

16

16

4000

2

20

22

24

20

20

4000

4

40

45

24

25

25

4000

8

80

90

24

36

38

3000

16

160

175

24

46

45

3000

25

250

275

24

50

49

2000

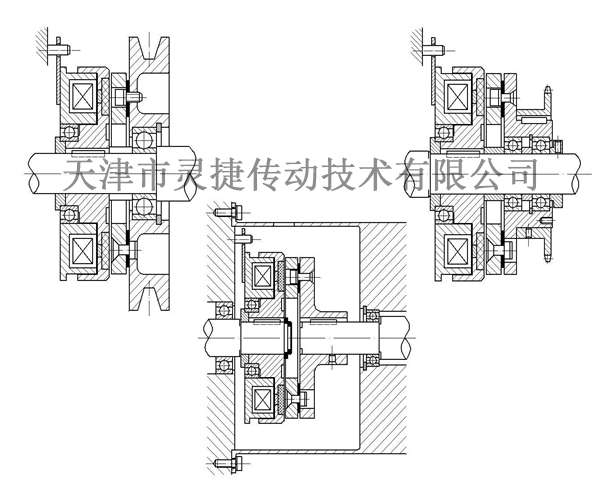

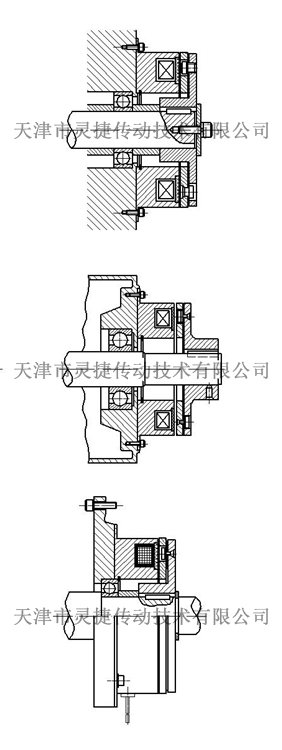

Installation Schematic

Installation Diagram

Installation Schematic

Installation Diagram

DDL3 DDL10 DZD10 series single-chip electromagnetic clutch (brake)

Classification

Keyword

Single-plate electromagnetic clutch

- Details

-

The single-plate electromagnetic clutch is a dry type electromagnetic clutch. If the installation, adjustment and maintenance are not in place, it is easy to cause the service life and working performance of the single-plate electromagnetic clutch to decrease.The common abnormalities of single-chip electromagnetic clutches are slipping or short life, which will affect normal operation. Most single-chip electromagnetic clutch users do not pay attention to the single-chip electromagnetic clutch working surface, cleaning work, the above-mentioned circumferential abnormal failure, one of the reasons for the use of the environment.

There are a lot of dust, water, oil, etc. in the use environment of single-chip electromagnetic clutches. These factors directly affect the service life and working performance of the entire electromagnetic clutch.

Therefore, the user must do a good job in daily maintenance, and cannot contact any water, oil, dust, etc. between and around the working single-piece electromagnetic clutch. The electromagnetic clutch coil controls the engagement and disengagement of the clutch.

Electromagnetic clutches are divided into: dry single-plate electromagnetic clutches, dry multi-plate electromagnetic clutches, wet multi-plate electromagnetic clutches, magnetic powder clutches, slip-type electromagnetic clutches, etc. The working principle of electromagnetic clutch can be divided into: power on and power off.

Dry single-plate electromagnetic clutch, when the coil generates electromagnetic force and the armature, the clutch is in the engaged state; when the clutch is in the disengaged state, the coil power supply is "armored".

Dry multi-disc wet multi-disc electromagnetic clutch: On the basis of the above principle, plus some other friction, the torque of the same volume is better than that of dry single-disc electromagnetic clutch. The wet multi-disc electromagnetic clutch must have oil cooling and lubrication. Magnetic powder clutch: magnetic powder is placed between the driving and driven parts. The magnetic powder in the loose state is not charged, and the electricity combines the magnetic powder with the driving part and the driven part to rotate at the same time.

Main performance parameters

Main Technical DataModel

ModelRated dynamic torque

Rated Torque

(N.M)static moment

Rated Static Torque

(N.M)Rated voltage

Rated Voltage

D.C(V)Coil power consumption (20 ℃)

Coil power(20℃) WMaximum allowable speed

Max Allowed Speed(r/min)Clutch

ClutchBrake

Brake0.4

4

4.4

24

-

12

4000

1

10

11

24

16

16

4000

2

20

22

24

20

20

4000

4

40

45

24

25

25

4000

8

80

90

24

36

38

3000

16

160

175

24

46

45

3000

25

250

275

24

50

49

2000

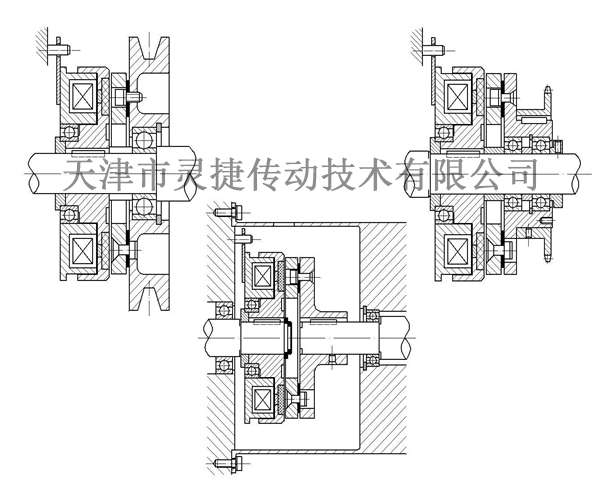

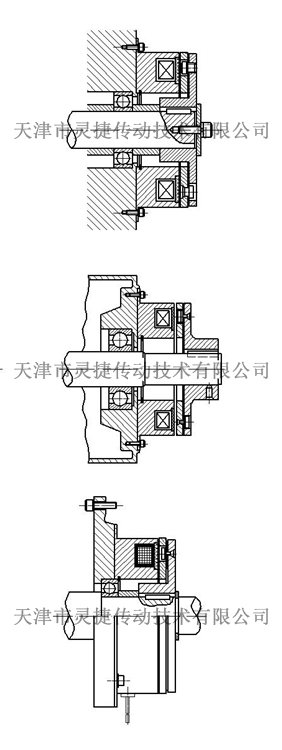

Installation Schematic

Installation Diagram

Installation Schematic

Installation Diagram

Product inquiry

The company has a product research and development department composed of experts, senior engineers and other professional and technical personnel. It is engaged in research and development and has perfect research and development test equipment. At present, the products reach more than 100 series of nearly 1,000 specifications, and the force distance ranges from 0.1N. m ~ 250000N.m. The company has been rated as a high-tech enterprise by the state for more than ten consecutive years, and a number of R & D projects have been established locally and have received municipal financial support.

Service Hotline:

Sales Department: Xu Jie

Sales Phone:+86-22-26616372, +86-22-26341260, +86 13920613215

Fax: 86-022-26616580

Market Development Department: Li Shuo

Marketing Department Telephone:+86-22-26614130

Technology Department: Yue Chao

Technical Department Telephone:+86-22-26222775 ,+86 18602228435

QQ:1059237223 1611412939

Company Website:www.tjlhq.com

Enterprise E-mail:xzm@tjlhq.com

Company address: No.6, Zone B, South Jifeng Road, Hongcang City Industrial Park, Yanji Daohong, Beichen District, Tianjin