Share

- Details

-

Single-chip electromagnetic clutch brake is mainly composed of yoke, coil, moving disc (single-chip electromagnetic brake without moving disc), friction plate, armature, flange and other integrated bodies. The working principle of the two is that when the coil is energized, a magnetic flux will be generated to attract the armature, thereby generating a friction torque, so that the driven part is combined or braked. Special attention should be paid:

1. When installing the single-chip electromagnetic clutch and single-chip electromagnetic brake, do not collide, drop or install it forcefully, otherwise it will cause deformation and affect the service life and performance.

2. The grease on the friction surface must be removed. Alcohol can be used to remove, it is strictly prohibited to pull or bend the lead.

3. When installing the single-piece electromagnetic clutch and brake, not only ensure the verticality between the mounting surface of the yoke and the shaft, but also ensure the coaxiality and axial positioning of the moving plate and the yoke, while maintaining the 0.8-1.5 gap. The set screw of the flange should be coated with anti-loosening glue before screwing in.

4. The movable plate and flange shall not be driven by force during installation. In order to prevent the deformation of the stop plate and flange, a special mounting sleeve should be used to make the installation more convenient.

The single-plate electromagnetic clutch is a dry type electromagnetic clutch. If the installation, adjustment and daily maintenance are not in place, it is easy to cause the service life and working performance of the single-plate electromagnetic clutch to decrease. The common abnormal phenomenon of single-plate electromagnetic clutch is slipping or short service life, which affects the normal operation of the machine.

Most users of single-chip electromagnetic clutches do not pay attention to the cleaning work between and around the working surfaces of the single-chip electromagnetic clutch. The occurrence of the above-mentioned abnormal failure is one of the reasons for the use environment.

For example, the use environment of the single-chip electromagnetic clutch has a lot of dust, moisture, oil, etc. The above factors directly affect the service life and working performance of the single-chip electromagnetic clutch. Therefore, the user must do a good job in the daily maintenance of the single-piece electromagnetic clutch and brake to prevent any moisture, oil or dust between the working surface of the single-piece electromagnetic clutch and the surrounding area.Dry single-chip electromagnetic clutch adopts high-quality non-asbestos disc with high friction coefficient, precision CNC lathe processing, many years of manufacturing experience and research and development, and high-quality equipment for material and technical manufacturing requirements. In the modern industrial machinery industry is widely used in cement equipment, coal equipment, iron and steel metallurgy, mining machinery, ships, paper machinery, rubber and plastics, petrochemical, lifting and transportation, beer and beverage, food packaging, pharmaceutical tanning, textile printing and dyeing, environmental protection equipment and other industries, is one of the needs of factories and enterprises equipment.

Many users do not know the advantages of electromagnetic clutch, or even do not know what the dry single-plate electromagnetic clutch is used for. Today, the advantages and applications of electromagnetic clutch are introduced.

Dry single-piece electromagnetic clutch is widely used in machine tools, packaging machinery, textile machinery, automation equipment, printing machinery, wire and cable machinery because of its advantages of high-speed response, strong durability, reliable action, simple structure, simple installation and maintenance. It is a kind of mechanical rotating part suitable for high-frequency action, which can be combined and separated from the active part when the active department is running.

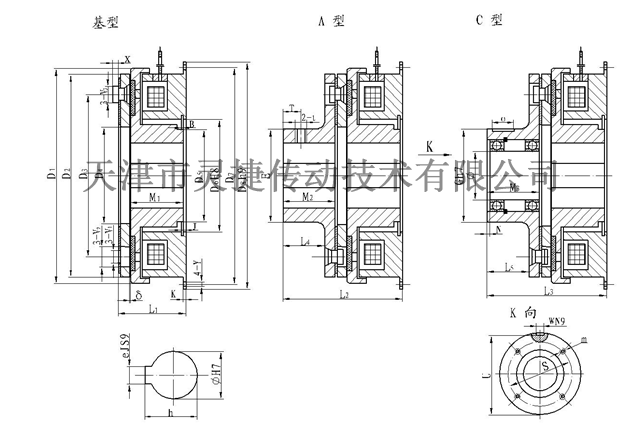

Outline and installation dimensions

Shape and Installation DimensionsSpecifications Model

D1

D2

D3

D4

D5

D6

D7

D8

L1

L2

L3

L4

L5

M1

M2

M3

J

B

1

85

80

60

41.5

28.5

42

90

100

31

51

60

16

25

24

20

29

4.3

1.7

2

106

100

76

51.5

40

52

112

125

36

61

71

20

30

27

25

35

5

2.2

4

133

125

95

61.5

45

62

137

150

40.5

70.5

86.5

24

40

30

30

46

5.5

2.2

8

169

160

120

79.5

62

80

175

190

46.5

84.5

103.5

31

50

34

38

57

6

2.7

16

212.5

200

158

100

78

100

215

230

55.5

97.5

124.5

33

60

40

42

69

7

2.7

25

253

241

185.5

120

90

120

260

280

62.5

112.5

139.5

38

65

45

50

77

8

3.2

Specifications Model

V1

V2

V3

Y

X

K

E

T

t

G

O

N

S

U

W

m

Φ

h

D1

Δ

1

4.1

8

7.5

5.5

2.8

2.5

31

8

M5

45

15

2

37

42-0.10

5

3-M4 Deep 6

15

17.30 0.1

5

0.2

2

5.1

10.5

9

6.5

3.8

3

41

10

M5

55

20

3

47

51.5-0.10

6

4-M4 Deep 8

20

22.80 0.1

6

0.2

4

6.1

12

11

6.5

5

3.5

49

12

M6

64

30

3

52

60-0.20

8

4-M4 Deep 8

25

28.30 0.2

8

0.3

8

8.1

15

14

9

6

4

65

15

M8

75

35

3

62

71-0.20

8

6-M5 Deep 8

30

33.30 0.2

8

0.3

16

10.2

20

18.5

9

8

5

83

16

M8

100

45

4

84

94.5-0.20

14

6-M6 Deep 12

45

48.80 0.2

14

0.5

25

10.2

20

18.5

11

8

6

100

18

M10

110

50

6

100

104-0.20

16

6-M6 Deep 12

55

59.30 0.2

16

0.5

DDL10 series single-plate electromagnetic clutch

Classification

Keyword

Single-plate electromagnetic clutch

- Details

-

Single-chip electromagnetic clutch brake is mainly composed of yoke, coil, moving disc (single-chip electromagnetic brake without moving disc), friction plate, armature, flange and other integrated bodies. The working principle of the two is that when the coil is energized, a magnetic flux will be generated to attract the armature, thereby generating a friction torque, so that the driven part is combined or braked. Special attention should be paid:

1. When installing the single-chip electromagnetic clutch and single-chip electromagnetic brake, do not collide, drop or install it forcefully, otherwise it will cause deformation and affect the service life and performance.

2. The grease on the friction surface must be removed. Alcohol can be used to remove, it is strictly prohibited to pull or bend the lead.

3. When installing the single-piece electromagnetic clutch and brake, not only ensure the verticality between the mounting surface of the yoke and the shaft, but also ensure the coaxiality and axial positioning of the moving plate and the yoke, while maintaining the 0.8-1.5 gap. The set screw of the flange should be coated with anti-loosening glue before screwing in.

4. The movable plate and flange shall not be driven by force during installation. In order to prevent the deformation of the stop plate and flange, a special mounting sleeve should be used to make the installation more convenient.

The single-plate electromagnetic clutch is a dry type electromagnetic clutch. If the installation, adjustment and daily maintenance are not in place, it is easy to cause the service life and working performance of the single-plate electromagnetic clutch to decrease. The common abnormal phenomenon of single-plate electromagnetic clutch is slipping or short service life, which affects the normal operation of the machine.

Most users of single-chip electromagnetic clutches do not pay attention to the cleaning work between and around the working surfaces of the single-chip electromagnetic clutch. The occurrence of the above-mentioned abnormal failure is one of the reasons for the use environment.

For example, the use environment of the single-chip electromagnetic clutch has a lot of dust, moisture, oil, etc. The above factors directly affect the service life and working performance of the single-chip electromagnetic clutch. Therefore, the user must do a good job in the daily maintenance of the single-piece electromagnetic clutch and brake to prevent any moisture, oil or dust between the working surface of the single-piece electromagnetic clutch and the surrounding area.Dry single-chip electromagnetic clutch adopts high-quality non-asbestos disc with high friction coefficient, precision CNC lathe processing, many years of manufacturing experience and research and development, and high-quality equipment for material and technical manufacturing requirements. In the modern industrial machinery industry is widely used in cement equipment, coal equipment, iron and steel metallurgy, mining machinery, ships, paper machinery, rubber and plastics, petrochemical, lifting and transportation, beer and beverage, food packaging, pharmaceutical tanning, textile printing and dyeing, environmental protection equipment and other industries, is one of the needs of factories and enterprises equipment.

Many users do not know the advantages of electromagnetic clutch, or even do not know what the dry single-plate electromagnetic clutch is used for. Today, the advantages and applications of electromagnetic clutch are introduced.

Dry single-piece electromagnetic clutch is widely used in machine tools, packaging machinery, textile machinery, automation equipment, printing machinery, wire and cable machinery because of its advantages of high-speed response, strong durability, reliable action, simple structure, simple installation and maintenance. It is a kind of mechanical rotating part suitable for high-frequency action, which can be combined and separated from the active part when the active department is running.

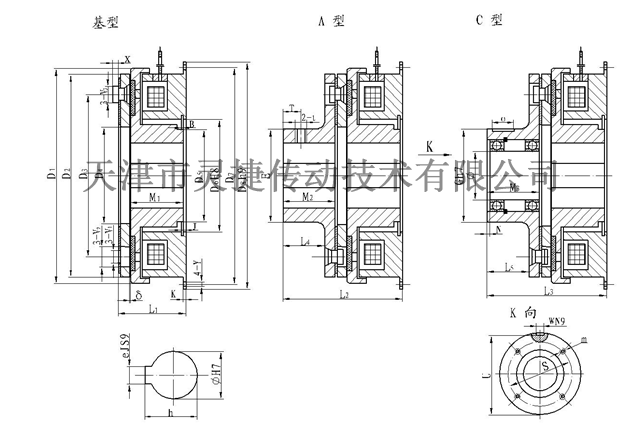

Outline and installation dimensions

Shape and Installation DimensionsSpecifications Model

D1

D2

D3

D4

D5

D6

D7

D8

L1

L2

L3

L4

L5

M1

M2

M3

J

B

1

85

80

60

41.5

28.5

42

90

100

31

51

60

16

25

24

20

29

4.3

1.7

2

106

100

76

51.5

40

52

112

125

36

61

71

20

30

27

25

35

5

2.2

4

133

125

95

61.5

45

62

137

150

40.5

70.5

86.5

24

40

30

30

46

5.5

2.2

8

169

160

120

79.5

62

80

175

190

46.5

84.5

103.5

31

50

34

38

57

6

2.7

16

212.5

200

158

100

78

100

215

230

55.5

97.5

124.5

33

60

40

42

69

7

2.7

25

253

241

185.5

120

90

120

260

280

62.5

112.5

139.5

38

65

45

50

77

8

3.2

Specifications Model

V1

V2

V3

Y

X

K

E

T

t

G

O

N

S

U

W

m

Φ

h

D1

Δ

1

4.1

8

7.5

5.5

2.8

2.5

31

8

M5

45

15

2

37

42-0.10

5

3-M4 Deep 6

15

17.30 0.1

5

0.2

2

5.1

10.5

9

6.5

3.8

3

41

10

M5

55

20

3

47

51.5-0.10

6

4-M4 Deep 8

20

22.80 0.1

6

0.2

4

6.1

12

11

6.5

5

3.5

49

12

M6

64

30

3

52

60-0.20

8

4-M4 Deep 8

25

28.30 0.2

8

0.3

8

8.1

15

14

9

6

4

65

15

M8

75

35

3

62

71-0.20

8

6-M5 Deep 8

30

33.30 0.2

8

0.3

16

10.2

20

18.5

9

8

5

83

16

M8

100

45

4

84

94.5-0.20

14

6-M6 Deep 12

45

48.80 0.2

14

0.5

25

10.2

20

18.5

11

8

6

100

18

M10

110

50

6

100

104-0.20

16

6-M6 Deep 12

55

59.30 0.2

16

0.5

Product inquiry

The company has a product research and development department composed of experts, senior engineers and other professional and technical personnel. It is engaged in research and development and has perfect research and development test equipment. At present, the products reach more than 100 series of nearly 1,000 specifications, and the force distance ranges from 0.1N. m ~ 250000N.m. The company has been rated as a high-tech enterprise by the state for more than ten consecutive years, and a number of R & D projects have been established locally and have received municipal financial support.

Service Hotline:

Sales Department: Xu Jie

Sales Phone:+86-22-26616372, +86-22-26341260, +86 13920613215

Fax: 86-022-26616580

Market Development Department: Li Shuo

Marketing Department Telephone:+86-22-26614130

Technology Department: Yue Chao

Technical Department Telephone:+86-22-26222775 ,+86 18602228435

QQ:1059237223 1611412939

Company Website:www.tjlhq.com

Enterprise E-mail:xzm@tjlhq.com

Company address: No.6, Zone B, South Jifeng Road, Hongcang City Industrial Park, Yanji Daohong, Beichen District, Tianjin