Share

- Details

-

The working principle of single-plate electromagnetic clutch

The driving part and the driven part of the single-chip electromagnetic clutch use the friction between the contact surfaces, or use liquid as the transmission medium (fluid coupling), or use magnetic transmission (electromagnetic clutch) to transmit torque, so that the two can be It can be temporarily separated, but can be gradually engaged, and the two parts are allowed to rotate with each other during the transmission process. At present, friction compressed by springs (referred to as friction clutches) is widely used in automobiles.

The torque from the engine is transmitted to the driven plate through the friction between the flywheel and the contact surface of the pressure plate and the driven plate. When the driver steps on the pedal, the large end of the diaphragm spring drives the pressure plate to move backward through the transmission of the mechanical parts. At this time, the driven part is separated from the driving part.

Single plate electromagnetic clutch installation matters needing attention:

1. Please use the dry electromagnetic clutch when there is no moisture, oil, etc. If the friction part is stained with moisture or oil, the friction torque will be greatly reduced, and the sensitivity of the clutch will also become worse. To avoid these situations in use, please add a cover.

2. Please use a protective cover when using it in a place with a lot of dust.

3. please use jis0401 h6 or js6 for the long axis size of the clutch. Use one of the keys specified in the jis b1301-1959 for mounting the shaft.

Taking into account the thermal expansion and other factors, the thrust of the installation shaft should be selected below 0.2mm.

5. During installation, please adjust the suction gap mechanically to within plus or minus 20% of the specified value.

6. Please keep the bracket light and do not use the bearing of the clutch to bear excessive pressure.

7. For the screws used for assembly, please use spring metal sheet, adhesive, etc. to prevent loosening.

8, the use of the mechanical side of the frame to maintain the lead at the same time, but also the use of terminal plates and other real connection.Many users do not know the advantages of electromagnetic clutch, or even do not know what the dry single-plate electromagnetic clutch is used for. Today, the advantages and applications of electromagnetic clutch are introduced.

Single-chip electromagnetic clutch is widely used in machine tools, packaging machinery, textile machinery, automation equipment, printing machinery, wire and cable machinery because of its high-speed response, strong durability, reliable action, simple structure, simple and convenient installation and maintenance. It is a kind of mechanical rotating part suitable for high-frequency action, which can combine and separate the driven part from the active part when the active department is running.

Single-chip electromagnetic clutch adopts high-quality non-asbestos disc with high friction coefficient, precision CNC lathe processing and many years of manufacturing experience and research and development, and high-quality equipment for material and technical manufacturing requirements. In the modern industrial machinery industry is widely used in cement equipment, coal equipment, iron and steel metallurgy, mining machinery, ships, paper machinery, rubber and plastics, petrochemical, lifting and transportation, beer and beverage, food packaging, pharmaceutical tanning, textile printing and dyeing, environmental protection equipment and other industries, is one of the needs of factories and enterprises equipment.

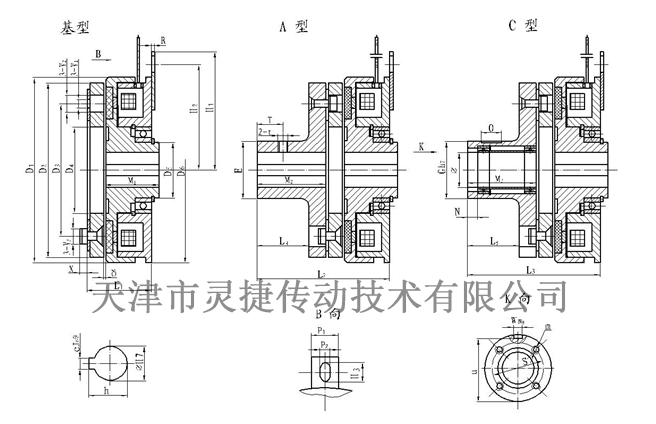

Outline and installation dimensions

Shape and Installation DimensionsSpecifications Model

D1

D2

D3

D4

D5

D6

L1

L2

L3

L4

L5

M1

M2

M3

R

H1

H2

H3

1

85

80

60

41.5

25

85

34.5

54.5

63.5

16

25

30

20

29

2

65

57

10.5

2

106

100

76

51.5

30

106

39

64

74

20

30

33

25

35

2

70

62.5

11.5

4

133

125

95

61.5

40

133

44.5

74.5

90.5

24

40

37.5

30

46

2

85

77

11.5

8

169

160

120

79.5

55

169

50.5

88.5

107.5

31

50

41.5

38

57

3.2

112

100

18.5

16

212.5

200

158

100

70

212.5

62

104

131

33

60

51

42

69

3.5

140

125

20

25

253

241

185.5

120

85

253

70.5

120.5

147.5

38

65

58

50

77

4.5

156.5

141.5

24

Specifications Model

P1

P2

V1

V2

V3

X

E

T

t

G

O

N

S

U

W

m

Φ

h

e

Δ

1

16

5.5

4.1

8

7.5

2.8

31

8

M5

45

15

2

37

42-0.10

5

3-M4 Deep 6

15

17.30 0.1

5

0.2

2

16

6.5

5.1

10.5

9

3.8

41

10

M5

55

20

3

47

51.5-0.10

6

4-M4 Deep 8

20

22.80 0.1

6

0.2

4

16

6.5

6.1

12

11

5

49

12

M6

64

30

3

52

60-0.20

8

4-M4 Deep 8

25

28.30 0.2

8

0.3

8

25

8.5

8.1

15

14

6

65

15

M8

75

35

3

62

71-0.20

8

6-M5 Deep 8

30

33.30 0.2

8

0.3

16

25

8.5

10.2

20

18.5

8

83

16

M8

100

45

4

84

94.5-0.20

14

6-M6 Deep 12

45

48.80 0.2

14

0.5

25

30

12.5

10.2

20

18.5

8

100

18

M10

110

50

6

100

104-0.20

16

6-M6 Deep 12

55

59.30 0.2

16

0.5

DDL3 series single-plate electromagnetic clutch

Classification

Keyword

Single-plate electromagnetic clutch

- Details

-

The working principle of single-plate electromagnetic clutch

The driving part and the driven part of the single-chip electromagnetic clutch use the friction between the contact surfaces, or use liquid as the transmission medium (fluid coupling), or use magnetic transmission (electromagnetic clutch) to transmit torque, so that the two can be It can be temporarily separated, but can be gradually engaged, and the two parts are allowed to rotate with each other during the transmission process. At present, friction compressed by springs (referred to as friction clutches) is widely used in automobiles.

The torque from the engine is transmitted to the driven plate through the friction between the flywheel and the contact surface of the pressure plate and the driven plate. When the driver steps on the pedal, the large end of the diaphragm spring drives the pressure plate to move backward through the transmission of the mechanical parts. At this time, the driven part is separated from the driving part.

Single plate electromagnetic clutch installation matters needing attention:

1. Please use the dry electromagnetic clutch when there is no moisture, oil, etc. If the friction part is stained with moisture or oil, the friction torque will be greatly reduced, and the sensitivity of the clutch will also become worse. To avoid these situations in use, please add a cover.

2. Please use a protective cover when using it in a place with a lot of dust.

3. please use jis0401 h6 or js6 for the long axis size of the clutch. Use one of the keys specified in the jis b1301-1959 for mounting the shaft.

Taking into account the thermal expansion and other factors, the thrust of the installation shaft should be selected below 0.2mm.

5. During installation, please adjust the suction gap mechanically to within plus or minus 20% of the specified value.

6. Please keep the bracket light and do not use the bearing of the clutch to bear excessive pressure.

7. For the screws used for assembly, please use spring metal sheet, adhesive, etc. to prevent loosening.

8, the use of the mechanical side of the frame to maintain the lead at the same time, but also the use of terminal plates and other real connection.Many users do not know the advantages of electromagnetic clutch, or even do not know what the dry single-plate electromagnetic clutch is used for. Today, the advantages and applications of electromagnetic clutch are introduced.

Single-chip electromagnetic clutch is widely used in machine tools, packaging machinery, textile machinery, automation equipment, printing machinery, wire and cable machinery because of its high-speed response, strong durability, reliable action, simple structure, simple and convenient installation and maintenance. It is a kind of mechanical rotating part suitable for high-frequency action, which can combine and separate the driven part from the active part when the active department is running.

Single-chip electromagnetic clutch adopts high-quality non-asbestos disc with high friction coefficient, precision CNC lathe processing and many years of manufacturing experience and research and development, and high-quality equipment for material and technical manufacturing requirements. In the modern industrial machinery industry is widely used in cement equipment, coal equipment, iron and steel metallurgy, mining machinery, ships, paper machinery, rubber and plastics, petrochemical, lifting and transportation, beer and beverage, food packaging, pharmaceutical tanning, textile printing and dyeing, environmental protection equipment and other industries, is one of the needs of factories and enterprises equipment.

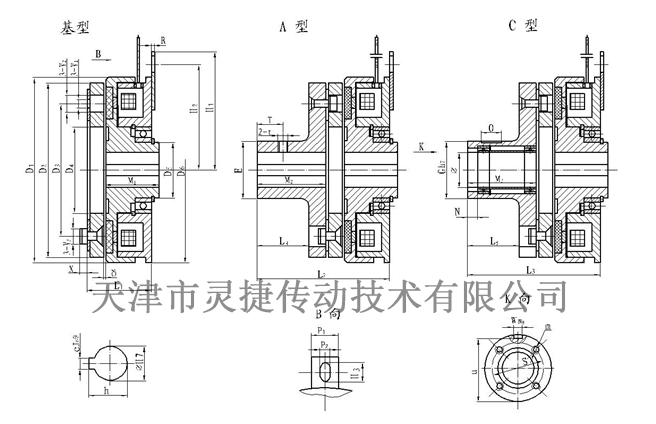

Outline and installation dimensions

Shape and Installation DimensionsSpecifications Model

D1

D2

D3

D4

D5

D6

L1

L2

L3

L4

L5

M1

M2

M3

R

H1

H2

H3

1

85

80

60

41.5

25

85

34.5

54.5

63.5

16

25

30

20

29

2

65

57

10.5

2

106

100

76

51.5

30

106

39

64

74

20

30

33

25

35

2

70

62.5

11.5

4

133

125

95

61.5

40

133

44.5

74.5

90.5

24

40

37.5

30

46

2

85

77

11.5

8

169

160

120

79.5

55

169

50.5

88.5

107.5

31

50

41.5

38

57

3.2

112

100

18.5

16

212.5

200

158

100

70

212.5

62

104

131

33

60

51

42

69

3.5

140

125

20

25

253

241

185.5

120

85

253

70.5

120.5

147.5

38

65

58

50

77

4.5

156.5

141.5

24

Specifications Model

P1

P2

V1

V2

V3

X

E

T

t

G

O

N

S

U

W

m

Φ

h

e

Δ

1

16

5.5

4.1

8

7.5

2.8

31

8

M5

45

15

2

37

42-0.10

5

3-M4 Deep 6

15

17.30 0.1

5

0.2

2

16

6.5

5.1

10.5

9

3.8

41

10

M5

55

20

3

47

51.5-0.10

6

4-M4 Deep 8

20

22.80 0.1

6

0.2

4

16

6.5

6.1

12

11

5

49

12

M6

64

30

3

52

60-0.20

8

4-M4 Deep 8

25

28.30 0.2

8

0.3

8

25

8.5

8.1

15

14

6

65

15

M8

75

35

3

62

71-0.20

8

6-M5 Deep 8

30

33.30 0.2

8

0.3

16

25

8.5

10.2

20

18.5

8

83

16

M8

100

45

4

84

94.5-0.20

14

6-M6 Deep 12

45

48.80 0.2

14

0.5

25

30

12.5

10.2

20

18.5

8

100

18

M10

110

50

6

100

104-0.20

16

6-M6 Deep 12

55

59.30 0.2

16

0.5

Product inquiry

The company has a product research and development department composed of experts, senior engineers and other professional and technical personnel. It is engaged in research and development and has perfect research and development test equipment. At present, the products reach more than 100 series of nearly 1,000 specifications, and the force distance ranges from 0.1N. m ~ 250000N.m. The company has been rated as a high-tech enterprise by the state for more than ten consecutive years, and a number of R & D projects have been established locally and have received municipal financial support.

Service Hotline:

Sales Department: Xu Jie

Sales Phone:+86-22-26616372, +86-22-26341260, +86 13920613215

Fax: 86-022-26616580

Market Development Department: Li Shuo

Marketing Department Telephone:+86-22-26614130

Technology Department: Yue Chao

Technical Department Telephone:+86-22-26222775 ,+86 18602228435

QQ:1059237223 1611412939

Company Website:www.tjlhq.com

Enterprise E-mail:xzm@tjlhq.com

Company address: No.6, Zone B, South Jifeng Road, Hongcang City Industrial Park, Yanji Daohong, Beichen District, Tianjin