Share

- Details

-

The working principle of the electromagnetic clutch: when the coil is energized, a magnetic force is generated. Under the action of the electromagnetic force, the spring plate of the armature is deformed. The moving disc and the "armature" are attracted together, and the clutch is in the engaged state; when the coil is de-energized, the magnetic force disappears, The "armature" bounces back under the action of the elastic force of the spring sheet, and the clutch is in a separated state.

The electromagnetic clutch is a friction clutch in which a pressing force is generated by an electromagnetic force. The function of the electromagnetic clutch is to transmit the torque (or power) of the actuator from the driving shaft to the driven shaft. It is widely used in various institutions (such as the transmission mechanism in machine tools and various electric mechanisms, etc.) to achieve fast start, braking, forward and reverse or speed control functions.

the role of electromagnetic clutch:

The electromagnetic clutch is a clutch with a clutch function under the action of electromagnetic force. The electromagnetic clutch controls the engagement and disengagement of the clutch by turning on and off the coil.

Electromagnetic clutches can be divided into: dry single-plate electromagnetic clutches, dry multi-plate electromagnetic clutches, wet multi-plate electromagnetic clutches, magnetic powder clutches, slip electromagnetic clutches, etc. Electromagnetic clutch according to the working mode can be divided into: power-on combination and power-off combination.

Electromagnetic clutch has the characteristics of high-speed response, strong durability, easy assembly and maintenance, and sure action. It is widely used in machine tools, packaging, printing, textiles, light industry, and office equipment.

The electromagnetic clutch controls the engagement and disengagement of the clutch by turning on and off the coil. Electromagnetic clutches can be divided into: dry single-plate electromagnetic clutches, dry multi-plate electromagnetic clutches, wet multi-plate electromagnetic clutches, magnetic powder clutches, slip electromagnetic clutches, etc. The working mode of electromagnetic clutch can be divided into: power-on combination and power-off combination.Main performance parameters

Main Technical DataSpecifications

ModelRated dynamic torque

Rated Torque

N.MRated static moment

Rated Static Torque

N.MOn time

Engagement Time

(≦)SDisconnection time

Disengagement

(≦)SRated voltage

Rated Voltage

D.C.VCoil power consumption (20 ℃)

CoilPower

(20℃)WMaximum allowable speed

Max Allowed Speed

r/minOil supply flow

Oil Flow Rates

L/min5S

50

90

0.28

0.11

24

29

3000

0.40

10S

100

160

—

—

24

41

2500

0.70

20S

200

320

0.45

0.21

24

46

2500

0.70

35S

350

560

0.50

0.26

24

52

1900

0.90

50S

500

800

0.56

0.31

24

65

1900

1.20

160S

1600

2500

1.23

0.48

24

132

1500

1.40

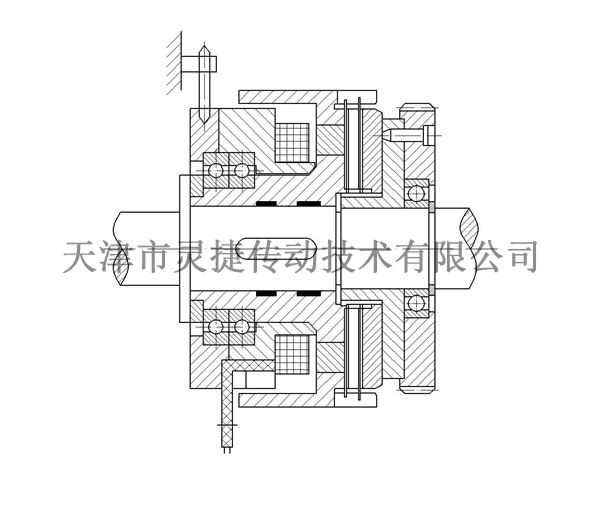

Installation Schematic

Installation Diagram

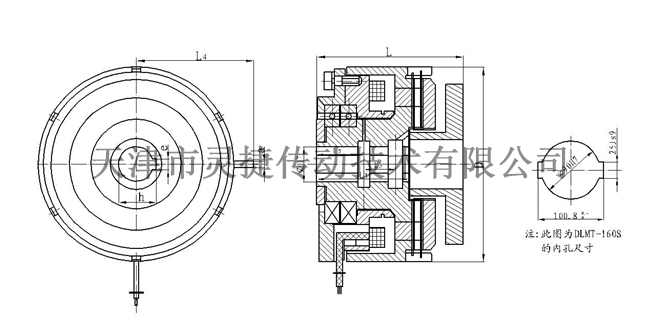

Outline and installation dimensions

Shape and Installation Dimensions

mm

Specifications Model

Radial Dimensions

Axial Dimensions

D1

Φ

e

h

Α

L

L1

L2

L3

L4

5s

113

30

8F8

31.70 0.2

——

78

58.5

29

22

——

10s

133

40

12F8

42 0 0.2

——

84.5

60

30

23

——

20s

157

50

14F8

52.5 0.05 0.15

——

89

61

30

24

——

35s

180

54

15F8

57 0.05 0.15

8

102

72

40

24

140

50s

195

60

18Js9

63.30 0.2

8

107

72.5

38.5

26

147

160s

295

90

2325Js9

100.80 0.4

12

205

140

80

52

190

Specifications Model

Number of teeth

Number of tooth(Z)Modulus

Modulus(a)Pressure angle

Preesure Angle(a)pitch circle diameter

Diameter of pitch CircleLength of common normal

The Base Tangent LengthMeasuring the number of span teeth

Tooth Number of Measuring Span5s

23

2

20°

46

15.4-0.150

3

10s

27

2

20°

54

21.3-0.15-0.065

4

20s

26

2.5

20°

65

19.3-0.20

3

35s

24

3

20°

72

23.15-0.20

3

50s

25

3

20°

75

23.19-0.20

3

160s

25

5

20°

125

38.65-0.30

3

DLMT Series Wet Multi-disc Electromagnetic Clutch

Classification

Keyword

Multi-disc electromagnetic clutch

- Details

-

The working principle of the electromagnetic clutch: when the coil is energized, a magnetic force is generated. Under the action of the electromagnetic force, the spring plate of the armature is deformed. The moving disc and the "armature" are attracted together, and the clutch is in the engaged state; when the coil is de-energized, the magnetic force disappears, The "armature" bounces back under the action of the elastic force of the spring sheet, and the clutch is in a separated state.

The electromagnetic clutch is a friction clutch in which a pressing force is generated by an electromagnetic force. The function of the electromagnetic clutch is to transmit the torque (or power) of the actuator from the driving shaft to the driven shaft. It is widely used in various institutions (such as the transmission mechanism in machine tools and various electric mechanisms, etc.) to achieve fast start, braking, forward and reverse or speed control functions.

the role of electromagnetic clutch:

The electromagnetic clutch is a clutch with a clutch function under the action of electromagnetic force. The electromagnetic clutch controls the engagement and disengagement of the clutch by turning on and off the coil.

Electromagnetic clutches can be divided into: dry single-plate electromagnetic clutches, dry multi-plate electromagnetic clutches, wet multi-plate electromagnetic clutches, magnetic powder clutches, slip electromagnetic clutches, etc. Electromagnetic clutch according to the working mode can be divided into: power-on combination and power-off combination.

Electromagnetic clutch has the characteristics of high-speed response, strong durability, easy assembly and maintenance, and sure action. It is widely used in machine tools, packaging, printing, textiles, light industry, and office equipment.

The electromagnetic clutch controls the engagement and disengagement of the clutch by turning on and off the coil. Electromagnetic clutches can be divided into: dry single-plate electromagnetic clutches, dry multi-plate electromagnetic clutches, wet multi-plate electromagnetic clutches, magnetic powder clutches, slip electromagnetic clutches, etc. The working mode of electromagnetic clutch can be divided into: power-on combination and power-off combination.Main performance parameters

Main Technical DataSpecifications

ModelRated dynamic torque

Rated Torque

N.MRated static moment

Rated Static Torque

N.MOn time

Engagement Time

(≦)SDisconnection time

Disengagement

(≦)SRated voltage

Rated Voltage

D.C.VCoil power consumption (20 ℃)

CoilPower

(20℃)WMaximum allowable speed

Max Allowed Speed

r/minOil supply flow

Oil Flow Rates

L/min5S

50

90

0.28

0.11

24

29

3000

0.40

10S

100

160

—

—

24

41

2500

0.70

20S

200

320

0.45

0.21

24

46

2500

0.70

35S

350

560

0.50

0.26

24

52

1900

0.90

50S

500

800

0.56

0.31

24

65

1900

1.20

160S

1600

2500

1.23

0.48

24

132

1500

1.40

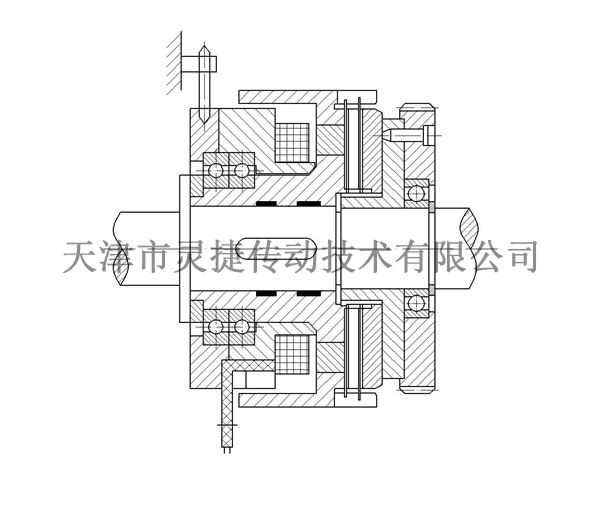

Installation Schematic

Installation Diagram

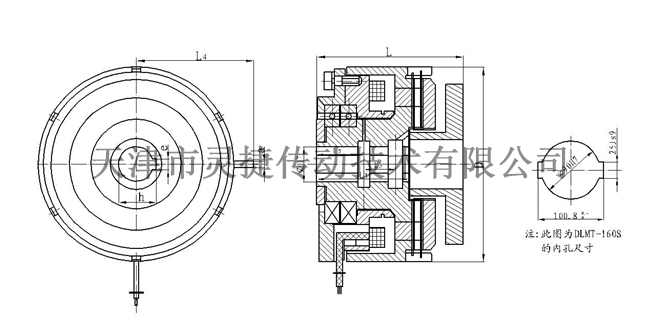

Outline and installation dimensions

Shape and Installation Dimensions

mm

Specifications Model

Radial Dimensions

Axial Dimensions

D1

Φ

e

h

Α

L

L1

L2

L3

L4

5s

113

30

8F8

31.70 0.2

——

78

58.5

29

22

——

10s

133

40

12F8

42 0 0.2

——

84.5

60

30

23

——

20s

157

50

14F8

52.5 0.05 0.15

——

89

61

30

24

——

35s

180

54

15F8

57 0.05 0.15

8

102

72

40

24

140

50s

195

60

18Js9

63.30 0.2

8

107

72.5

38.5

26

147

160s

295

90

2325Js9

100.80 0.4

12

205

140

80

52

190

Specifications Model

Number of teeth

Number of tooth(Z)Modulus

Modulus(a)Pressure angle

Preesure Angle(a)pitch circle diameter

Diameter of pitch CircleLength of common normal

The Base Tangent LengthMeasuring the number of span teeth

Tooth Number of Measuring Span5s

23

2

20°

46

15.4-0.150

3

10s

27

2

20°

54

21.3-0.15-0.065

4

20s

26

2.5

20°

65

19.3-0.20

3

35s

24

3

20°

72

23.15-0.20

3

50s

25

3

20°

75

23.19-0.20

3

160s

25

5

20°

125

38.65-0.30

3

Product inquiry

The company has a product research and development department composed of experts, senior engineers and other professional and technical personnel. It is engaged in research and development and has perfect research and development test equipment. At present, the products reach more than 100 series of nearly 1,000 specifications, and the force distance ranges from 0.1N. m ~ 250000N.m. The company has been rated as a high-tech enterprise by the state for more than ten consecutive years, and a number of R & D projects have been established locally and have received municipal financial support.

Service Hotline:

Sales Department: Xu Jie

Sales Phone:+86-22-26616372, +86-22-26341260, +86 13920613215

Fax: 86-022-26616580

Market Development Department: Li Shuo

Marketing Department Telephone:+86-22-26614130

Technology Department: Yue Chao

Technical Department Telephone:+86-22-26222775 ,+86 18602228435

QQ:1059237223 1611412939

Company Website:www.tjlhq.com

Enterprise E-mail:xzm@tjlhq.com

Company address: No.6, Zone B, South Jifeng Road, Hongcang City Industrial Park, Yanji Daohong, Beichen District, Tianjin