Share

- Details

-

In order to ensure the uninterrupted operation of the electromagnetic clutch, it must be maintained and maintained frequently:

1. Always check the tightening degree of the bolts, especially tighten the bolts of the electromagnet, the bolts of the electromagnet and the housing, the bolts of the yoke, the bolts of the electromagnet coil and the terminal bolts.

2. Lubricant is often added to the movable part of the electromagnetic clutch.

3. Regularly check the mechanical wear of the movable parts, and remove the dust, flower hair and dirt on the surface of the electromagnet parts.

4. Regularly check the length of the armature stroke. This is because, during operation of the clutch, the stroke length of the armature will increase due to wear of the cutting surface. When the armature stroke length does not reach the normal value, it must be adjusted to restore the minimum gap between the braking surface and the turntable. If the armature stroke length is increased above the normal value, the suction force may be greatly reduced.

5. If the worn braking surface is replaced, the minimum clearance between the braking surface and the turntable should be properly adjusted.

During use, the electromagnetic clutch will have different failures due to various factors. The general failure of the electromagnetic clutch mostly occurs during starting, idling and load, but it occurs more often during the starting period, mainly manifested as failure to start, or the voltage input to the electromagnetic clutch is too low, and the regular input voltage is DC24V. As well as unstable power, slippage or high temperature, but there are also special circumstances.

Therefore, pay attention to the requirements when inputting the voltage. The elimination method is to detect whether the input voltage is the required voltage of the electromagnetic clutch. The coil is short-circuited, and this kind of fault is usually replaced or repaired. It is recommended to replace or modify the electromagnetic clutch circuit.Main performance parameters

Main Technical DataSpecifications

ModelRated dynamic torque

Rated Torque

(N.M)Rated static moment

Rated Static Torque N.mno-load moment

Drag Torque

(≦) N.mOn time

Engagement Time

(≦)SDisconnection time

Disengagement Time

(≦)SRated voltage

Rated Voltage

D.C(V)Coil power consumption (20 ℃)

Coilpower(20℃)WMaximum allowable speed

Max Allowed Speed(r/min)Weight

weighnt(kg)1A/1A.G

12.5

20/14

0.088/0.05

0.14/0.11

0.03/0.025

24

26

3000

2

2A/2A.G

25

40/27.5

0.175/0.10

0.18/0.14

0.032/0.028

24

27

3000

2.6

4A/4A.G

40

63/44

0.280/0.16

0.20/0.18

0.04/0.03

24

33

3000

3.2

6A/6A.G

63

100/70

0.350/0.26

0.25/0.20

0.045/0.04

24

43

3000

4

10A/10A.G

100

160/110

0.500/0.35

0.28/0.25

0.06/0.045

24

43

3000

5.5

16A/16A.G

160

250/175

1.00/0.56

0.30/0.28

0.08/0.06

24

47

2500

7.8

25A/25A.G

250

400/280

1.50/0.88

0.35/0.30

0.11/0.08

24

55

2200

11

40A/40A.G

400

630/440

2.50/1.40

0.40/0.35

0.12/0.11

24

62

2000

15

63A/63A.G

630

1000/700

4.00/2.20

0.50/0.40

0.15/0.12

24

70

1750

21

100A/100A.G

1000

1600/1100

6.00/3.00

0.60/0.50

0.18/0.15

24

79

1600

32

160A/160A.G

1600

2500/1750

10/5.5

0.90/0.70

0.22/0.18

24

93

1350

50

250A/250A

2500

4000/2750

15/8.6

1.15/0.90

0.28/0.25

24

110

1200

77

400A/400A.G

4000

6300/4400

24/14

1.30/1.20

0.35/0.30

24

123

1000

122

630A.G

6300

6800

22.5

2.1

0.4

24

137

900

194

1000A.G

10000

11000

36

3.6

0.6

24

180

750

300

Note: G is dry multi-disc electromagnetic clutch

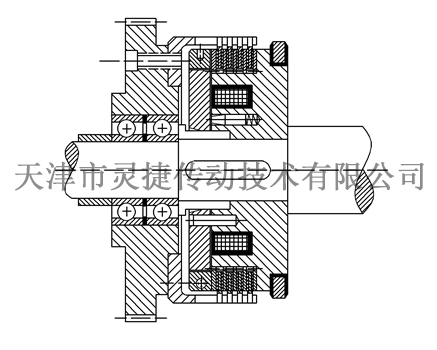

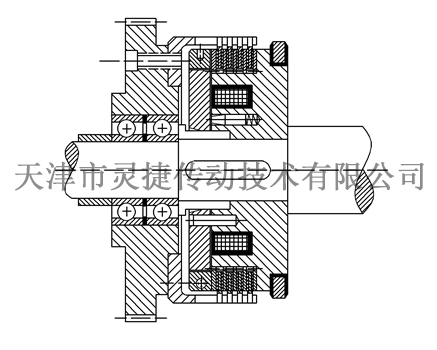

Note: G express the electromagnetic multidisc clutch of dry operationInstallation Schematic

Installation Diagram

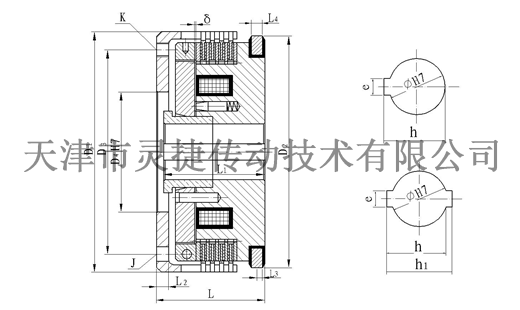

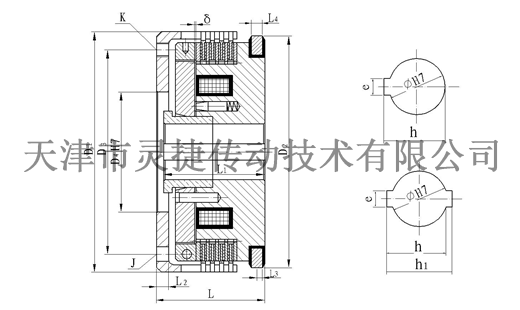

Outline and installation dimensions

Shape and Installation Dimensions

Specifications

ModelRadial Dimensions

Axial dimension

Axial DimensionsBrush model

Brush ModelD1

D2

D3

D4

Φ

e

h

J

K

L

L1

L2

L3

L4

E

1A/ 1A.G

100

100

85

50

18

50 0.025

19.9 0.14

2Xφ6

4XM6

45

42

5

5.5

8

0.30

wet

Adopt

DS-005

dry type

Adopt

DS-006

2A/ 2A.G

110

110

90

55

20

60 0.025

22.3 0.14

2Xφ6

4XM6

48

45

5

5.5

8

0.30

4A/ 4A.G

120

120

100

60

25

80 0.03

27.6 0.14

3Xφ6

6XM6

52

48

6

5.5

8

0.30

6A/6A.G

132

132

105

65

30

80 0.03

32.6 0.17

3Xφ6

6XM8

55

50

7

5.5

8

0.30

10A/ 10A.G

147

145

120

75

40

120 0.035

42.9 0.17

3Xφ8

6XM8

58

53

7

5.5

8

0.35

16A/ 16A.G

162

160

135

85

45

140 0.035

48.3 0.17

3Xφ8

6XM8

62

57

7

5.5

8

0.40

25A/ 25A.G

182

180

155

95

50

160 0.035

53.60 0.20

3Xφ10

6X M10

68

63

8

6

8

0.45

40A/ 40A.G

202

200

170

120

60

180 0.035

64 0.20

3Xφ10

6X M10

76

70

9

6.25

8

0.50

63A/ 63A.G

235

230

200

125

70

200 0.0435

74.3 0.20

3Xφ14

6X M12

86

80

10

6.25

8

0.60

100A/ 100A.G

270

255

235

150

70

200 0.0435

74.3 0.20

3Xφ14

6X M12

100

92

12

8.5

10

0.70

160A/ 160A.G

310

295

260

180H8

75

20±0.026

81.1 0.20

3Xφ16

6X M16

115

107

14

8

10

0.80

250A/ 250A.G

360

340

305

200H8

100

28±0.026

106.4 0.20

3Xφ16

6X M16

132

122

15

8.5

10

0.90

400A/ 400A.G

420

395

350

235H8

120

320 0.05

126.7 0.20

4Xφ20

6X M16

150

138

17

8.5

10

1

630A.G

485

455

400

235 H8

130

32 0.01 0.07

136.7 0.20

4Xφ20

8X M20

172

157

20

10.5

12

1.1

1000A.G

560

530

460

280

145

32±0.03

154.2 0.20

4Xφ25

4X M24

200

183

22

10.5

12

1.3.

Note: 1. D3, J and K listed in the table are user connection dimensions, which are processed by the user. The data in this table are for reference only.

2.250A/250AG,400A/ 400A.G, 630A.G, 1000A.G,G is a double bond hole, the position is 180, h1 is 112.80 0.2,113.40 0.52,143.40 0.52,163.40 0.2

Remark:1. D3、J、K list in the list are sizes using for join of customer and processed by customer himself. The data of this list are for reference only

2. 250A/250AG,400A/ 400A.G、630A.G、1000A.G,G are double-Kay hole. The position in 180°,h1 is 112.8 plus0 0.2,133.4 plus0 0.52,143.4 plus0 0.52,163.4 plus0 0.2

DLM10 Series (EKE Series) Multi-disc Electromagnetic Clutch

Classification

Keyword

Multi-disc electromagnetic clutch

- Details

-

In order to ensure the uninterrupted operation of the electromagnetic clutch, it must be maintained and maintained frequently:

1. Always check the tightening degree of the bolts, especially tighten the bolts of the electromagnet, the bolts of the electromagnet and the housing, the bolts of the yoke, the bolts of the electromagnet coil and the terminal bolts.

2. Lubricant is often added to the movable part of the electromagnetic clutch.

3. Regularly check the mechanical wear of the movable parts, and remove the dust, flower hair and dirt on the surface of the electromagnet parts.

4. Regularly check the length of the armature stroke. This is because, during operation of the clutch, the stroke length of the armature will increase due to wear of the cutting surface. When the armature stroke length does not reach the normal value, it must be adjusted to restore the minimum gap between the braking surface and the turntable. If the armature stroke length is increased above the normal value, the suction force may be greatly reduced.

5. If the worn braking surface is replaced, the minimum clearance between the braking surface and the turntable should be properly adjusted.

During use, the electromagnetic clutch will have different failures due to various factors. The general failure of the electromagnetic clutch mostly occurs during starting, idling and load, but it occurs more often during the starting period, mainly manifested as failure to start, or the voltage input to the electromagnetic clutch is too low, and the regular input voltage is DC24V. As well as unstable power, slippage or high temperature, but there are also special circumstances.

Therefore, pay attention to the requirements when inputting the voltage. The elimination method is to detect whether the input voltage is the required voltage of the electromagnetic clutch. The coil is short-circuited, and this kind of fault is usually replaced or repaired. It is recommended to replace or modify the electromagnetic clutch circuit.Main performance parameters

Main Technical DataSpecifications

ModelRated dynamic torque

Rated Torque

(N.M)Rated static moment

Rated Static Torque N.mno-load moment

Drag Torque

(≦) N.mOn time

Engagement Time

(≦)SDisconnection time

Disengagement Time

(≦)SRated voltage

Rated Voltage

D.C(V)Coil power consumption (20 ℃)

Coilpower(20℃)WMaximum allowable speed

Max Allowed Speed(r/min)Weight

weighnt(kg)1A/1A.G

12.5

20/14

0.088/0.05

0.14/0.11

0.03/0.025

24

26

3000

2

2A/2A.G

25

40/27.5

0.175/0.10

0.18/0.14

0.032/0.028

24

27

3000

2.6

4A/4A.G

40

63/44

0.280/0.16

0.20/0.18

0.04/0.03

24

33

3000

3.2

6A/6A.G

63

100/70

0.350/0.26

0.25/0.20

0.045/0.04

24

43

3000

4

10A/10A.G

100

160/110

0.500/0.35

0.28/0.25

0.06/0.045

24

43

3000

5.5

16A/16A.G

160

250/175

1.00/0.56

0.30/0.28

0.08/0.06

24

47

2500

7.8

25A/25A.G

250

400/280

1.50/0.88

0.35/0.30

0.11/0.08

24

55

2200

11

40A/40A.G

400

630/440

2.50/1.40

0.40/0.35

0.12/0.11

24

62

2000

15

63A/63A.G

630

1000/700

4.00/2.20

0.50/0.40

0.15/0.12

24

70

1750

21

100A/100A.G

1000

1600/1100

6.00/3.00

0.60/0.50

0.18/0.15

24

79

1600

32

160A/160A.G

1600

2500/1750

10/5.5

0.90/0.70

0.22/0.18

24

93

1350

50

250A/250A

2500

4000/2750

15/8.6

1.15/0.90

0.28/0.25

24

110

1200

77

400A/400A.G

4000

6300/4400

24/14

1.30/1.20

0.35/0.30

24

123

1000

122

630A.G

6300

6800

22.5

2.1

0.4

24

137

900

194

1000A.G

10000

11000

36

3.6

0.6

24

180

750

300

Note: G is dry multi-disc electromagnetic clutch

Note: G express the electromagnetic multidisc clutch of dry operationInstallation Schematic

Installation Diagram

Outline and installation dimensions

Shape and Installation Dimensions

Specifications

ModelRadial Dimensions

Axial dimension

Axial DimensionsBrush model

Brush ModelD1

D2

D3

D4

Φ

e

h

J

K

L

L1

L2

L3

L4

E

1A/ 1A.G

100

100

85

50

18

50 0.025

19.9 0.14

2Xφ6

4XM6

45

42

5

5.5

8

0.30

wet

Adopt

DS-005

dry type

Adopt

DS-006

2A/ 2A.G

110

110

90

55

20

60 0.025

22.3 0.14

2Xφ6

4XM6

48

45

5

5.5

8

0.30

4A/ 4A.G

120

120

100

60

25

80 0.03

27.6 0.14

3Xφ6

6XM6

52

48

6

5.5

8

0.30

6A/6A.G

132

132

105

65

30

80 0.03

32.6 0.17

3Xφ6

6XM8

55

50

7

5.5

8

0.30

10A/ 10A.G

147

145

120

75

40

120 0.035

42.9 0.17

3Xφ8

6XM8

58

53

7

5.5

8

0.35

16A/ 16A.G

162

160

135

85

45

140 0.035

48.3 0.17

3Xφ8

6XM8

62

57

7

5.5

8

0.40

25A/ 25A.G

182

180

155

95

50

160 0.035

53.60 0.20

3Xφ10

6X M10

68

63

8

6

8

0.45

40A/ 40A.G

202

200

170

120

60

180 0.035

64 0.20

3Xφ10

6X M10

76

70

9

6.25

8

0.50

63A/ 63A.G

235

230

200

125

70

200 0.0435

74.3 0.20

3Xφ14

6X M12

86

80

10

6.25

8

0.60

100A/ 100A.G

270

255

235

150

70

200 0.0435

74.3 0.20

3Xφ14

6X M12

100

92

12

8.5

10

0.70

160A/ 160A.G

310

295

260

180H8

75

20±0.026

81.1 0.20

3Xφ16

6X M16

115

107

14

8

10

0.80

250A/ 250A.G

360

340

305

200H8

100

28±0.026

106.4 0.20

3Xφ16

6X M16

132

122

15

8.5

10

0.90

400A/ 400A.G

420

395

350

235H8

120

320 0.05

126.7 0.20

4Xφ20

6X M16

150

138

17

8.5

10

1

630A.G

485

455

400

235 H8

130

32 0.01 0.07

136.7 0.20

4Xφ20

8X M20

172

157

20

10.5

12

1.1

1000A.G

560

530

460

280

145

32±0.03

154.2 0.20

4Xφ25

4X M24

200

183

22

10.5

12

1.3.

Note: 1. D3, J and K listed in the table are user connection dimensions, which are processed by the user. The data in this table are for reference only.

2.250A/250AG,400A/ 400A.G, 630A.G, 1000A.G,G is a double bond hole, the position is 180, h1 is 112.80 0.2,113.40 0.52,143.40 0.52,163.40 0.2

Remark:1. D3、J、K list in the list are sizes using for join of customer and processed by customer himself. The data of this list are for reference only

2. 250A/250AG,400A/ 400A.G、630A.G、1000A.G,G are double-Kay hole. The position in 180°,h1 is 112.8 plus0 0.2,133.4 plus0 0.52,143.4 plus0 0.52,163.4 plus0 0.2

Product inquiry

The company has a product research and development department composed of experts, senior engineers and other professional and technical personnel. It is engaged in research and development and has perfect research and development test equipment. At present, the products reach more than 100 series of nearly 1,000 specifications, and the force distance ranges from 0.1N. m ~ 250000N.m. The company has been rated as a high-tech enterprise by the state for more than ten consecutive years, and a number of R & D projects have been established locally and have received municipal financial support.

Service Hotline:

Sales Department: Xu Jie

Sales Phone:+86-22-26616372, +86-22-26341260, +86 13920613215

Fax: 86-022-26616580

Market Development Department: Li Shuo

Marketing Department Telephone:+86-22-26614130

Technology Department: Yue Chao

Technical Department Telephone:+86-22-26222775 ,+86 18602228435

QQ:1059237223 1611412939

Company Website:www.tjlhq.com

Enterprise E-mail:xzm@tjlhq.com

Company address: No.6, Zone B, South Jifeng Road, Hongcang City Industrial Park, Yanji Daohong, Beichen District, Tianjin