Share

- Details

-

The driving part and the driven part of the single-chip electromagnetic clutch use the friction between the contact surfaces, or use liquid as the transmission medium (fluid coupling), or use magnetic transmission (electromagnetic clutch) to transmit torque, so that the two can be temporarily separated, and can be gradually engaged, and the two parts are allowed to rotate with each other during the transmission process.

After the single-chip electromagnetic clutch is energized (the standard voltage is 24 V DC), the coil generates a strong magnetic field, and the armature plate is attracted to the electromagnetic brake yoke or the friction bushing of the electromagnetic clutch rotor under the action of the magnetic field force. The driving or braking torque is transmitted through the plate spring, and there is no slip during operation and no abrasion after connection. After the power loss, the armature plate leaves the electromagnetic brake yoke or the bushing of the electromagnetic clutch rotor under the action of the plate spring force to prepare for the next action. There is no residual torque when released. The electromagnetic clutch/electromagnetic brake can be installed horizontally or vertically to achieve torque transmission, regardless of high-speed or no-load rotation resistance.

Characteristics of single-plate electromagnetic clutch

1. High-speed response: Because it is a dry type, the torque is transmitted quickly and convenient action can be achieved.

2, durability: good heat dissipation, and the use of advanced materials, even high-frequency, high-energy use, but also very durable.

3. Easy assembly and maintenance: the magnetic field coil hidden in the ball bearing is static, so there is no need to take out the middle core or use carbon brushes, and the use is simple. 4, the action is true: the use of plate shrapnel, although there is a strong vibration will not produce loose, good durability.

The driving part and the driven part of the single-chip electromagnetic clutch use the friction between the contact surfaces, or use liquid as the transmission medium (fluid coupling), or use magnetic transmission (electromagnetic clutch) to transmit torque, so that the two can be It can be temporarily separated, but can be gradually engaged, and the two parts are allowed to rotate with each other during the transmission process.The so-called clutch, as the name implies, means to use "off" and "on" to transmit an appropriate amount of power. The clutch consists of a friction plate, a spring plate, a pressure plate and a power output shaft. It is located between the engine and the gearbox and is used to transmit the torque stored on the engine flywheel to the gearbox to ensure that the vehicle is transmitted to the gearbox under different driving conditions. The appropriate amount of driving force and torque of the driving wheel belongs to the category of powertrain. In the case of semi-linkage, the power input end and the power output end of the clutch are allowed to have a speed difference, that is, the appropriate amount of power can be transmitted through the speed difference.

The driving part and the driven part of the single-plate electromagnetic clutch use the friction between the contact surfaces to transmit torque with magnetic transmission, so that the two can be temporarily separated and gradually engaged, and the two parts are allowed to rotate with each other during the transmission process.

The single-plate electromagnetic clutch can be installed coaxially or on the shaft. The axial direction must be fixed. The driving part and the driven part are not allowed to move axially. When the shaft is installed, the driving part and the driven

The coaxiality between the partial shafts shall not be greater than 0.1mm. Before installation, it must be cleaned to remove anti-rust grease and sundries.

Single-plate electromagnetic clutch and brake shall be class B insulated with normal temperature rise of 40°C. The working temperature at the limit thermal equilibrium is not allowed to exceed 100°C, otherwise the coil and the friction part are prone to damage. Electricity.

Source and control circuit, clutch power supply is generally 24 volts DC (except for special orders).

Main performance parameters

Main Technical DataModel

ModelRated dynamic torque

Rated Torque

(N.M)static moment

Rated Static Torque (N.m)Rated voltage

Rated Voltage

D.C(V)Coil power consumption (20 ℃)

Coil power(20℃) WMaximum allowable speed

Max Allowed Speed(r/min)DLD1-100

1000

1100

24

125

1500

110

DLD1-100A

1000

1100

24

125

1500

110

DLD1-100T

1000

1100

24

125

1500

110

DLD1-160A

1600

1760

110

151

1000

DLD1-160AT

1600

1760

110

151

1000

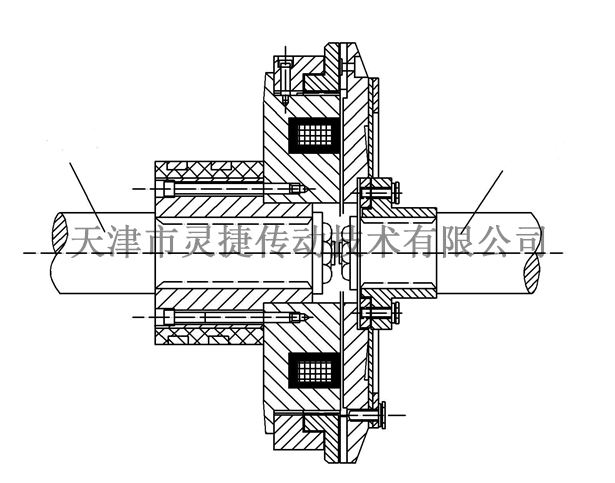

Installation Schematic

Installation Diagram

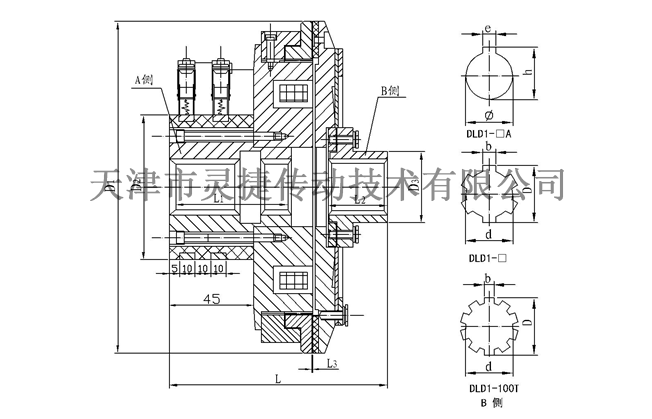

Outline and installation dimensions

Shape and Installation Dimensions

Model

Radial Dimensions

Axial Dimensions

Brush model

Brush ModelD1

D2

D3

L

L1

L2

L3

Δ

DLD1-100

420

170

90

212

105

75

0.7

0.8±0.1

DS-010

DLD1-100A

420

170

90

212

105

75

0.7

0.8±0.1

DLD1-100T

420

170

60

216

117

58

0.7

0.8±0.1

DLD1-160A

480

200

110

259

110

100

0.8

1±0.1

DLD1-160AT

480

200

100

270

110

110

0.8

1±0.1

Model

轴孔尺寸Dimensions of the Shaft Hole

A侧 A Side

B侧 B Side

D

d

b

Φ

h

e

D

d

b

Φ

h

e

DLD1-100

600 0.03

540 0.2

140.045 0.105

600 0.03

540 0.2

140.045 0.105

DLD1-100A

60H7

64.40 0.2

18JS9

60H7

64.40 0.2

18JS9

DLD1-100T

600 0.03

540 0.2

140.045 0.105

380 0.027

330 0.34

60.017 0.040

DLD1-160A

65H7

70.6H11

18JS9

75H7

81.1H11

20JS9

DLD1-160AT

70H7

74.30 0.2

20

55H7

58.60 0.2

160 0.035

DLD1-100.100A.100T.160A.160AT single-plate electromagnetic clutch

Classification

Keyword

Single-plate electromagnetic clutch

- Details

-

The driving part and the driven part of the single-chip electromagnetic clutch use the friction between the contact surfaces, or use liquid as the transmission medium (fluid coupling), or use magnetic transmission (electromagnetic clutch) to transmit torque, so that the two can be temporarily separated, and can be gradually engaged, and the two parts are allowed to rotate with each other during the transmission process.

After the single-chip electromagnetic clutch is energized (the standard voltage is 24 V DC), the coil generates a strong magnetic field, and the armature plate is attracted to the electromagnetic brake yoke or the friction bushing of the electromagnetic clutch rotor under the action of the magnetic field force. The driving or braking torque is transmitted through the plate spring, and there is no slip during operation and no abrasion after connection. After the power loss, the armature plate leaves the electromagnetic brake yoke or the bushing of the electromagnetic clutch rotor under the action of the plate spring force to prepare for the next action. There is no residual torque when released. The electromagnetic clutch/electromagnetic brake can be installed horizontally or vertically to achieve torque transmission, regardless of high-speed or no-load rotation resistance.

Characteristics of single-plate electromagnetic clutch

1. High-speed response: Because it is a dry type, the torque is transmitted quickly and convenient action can be achieved.

2, durability: good heat dissipation, and the use of advanced materials, even high-frequency, high-energy use, but also very durable.

3. Easy assembly and maintenance: the magnetic field coil hidden in the ball bearing is static, so there is no need to take out the middle core or use carbon brushes, and the use is simple. 4, the action is true: the use of plate shrapnel, although there is a strong vibration will not produce loose, good durability.

The driving part and the driven part of the single-chip electromagnetic clutch use the friction between the contact surfaces, or use liquid as the transmission medium (fluid coupling), or use magnetic transmission (electromagnetic clutch) to transmit torque, so that the two can be It can be temporarily separated, but can be gradually engaged, and the two parts are allowed to rotate with each other during the transmission process.The so-called clutch, as the name implies, means to use "off" and "on" to transmit an appropriate amount of power. The clutch consists of a friction plate, a spring plate, a pressure plate and a power output shaft. It is located between the engine and the gearbox and is used to transmit the torque stored on the engine flywheel to the gearbox to ensure that the vehicle is transmitted to the gearbox under different driving conditions. The appropriate amount of driving force and torque of the driving wheel belongs to the category of powertrain. In the case of semi-linkage, the power input end and the power output end of the clutch are allowed to have a speed difference, that is, the appropriate amount of power can be transmitted through the speed difference.

The driving part and the driven part of the single-plate electromagnetic clutch use the friction between the contact surfaces to transmit torque with magnetic transmission, so that the two can be temporarily separated and gradually engaged, and the two parts are allowed to rotate with each other during the transmission process.

The single-plate electromagnetic clutch can be installed coaxially or on the shaft. The axial direction must be fixed. The driving part and the driven part are not allowed to move axially. When the shaft is installed, the driving part and the driven

The coaxiality between the partial shafts shall not be greater than 0.1mm. Before installation, it must be cleaned to remove anti-rust grease and sundries.

Single-plate electromagnetic clutch and brake shall be class B insulated with normal temperature rise of 40°C. The working temperature at the limit thermal equilibrium is not allowed to exceed 100°C, otherwise the coil and the friction part are prone to damage. Electricity.

Source and control circuit, clutch power supply is generally 24 volts DC (except for special orders).

Main performance parameters

Main Technical DataModel

ModelRated dynamic torque

Rated Torque

(N.M)static moment

Rated Static Torque (N.m)Rated voltage

Rated Voltage

D.C(V)Coil power consumption (20 ℃)

Coil power(20℃) WMaximum allowable speed

Max Allowed Speed(r/min)DLD1-100

1000

1100

24

125

1500

110

DLD1-100A

1000

1100

24

125

1500

110

DLD1-100T

1000

1100

24

125

1500

110

DLD1-160A

1600

1760

110

151

1000

DLD1-160AT

1600

1760

110

151

1000

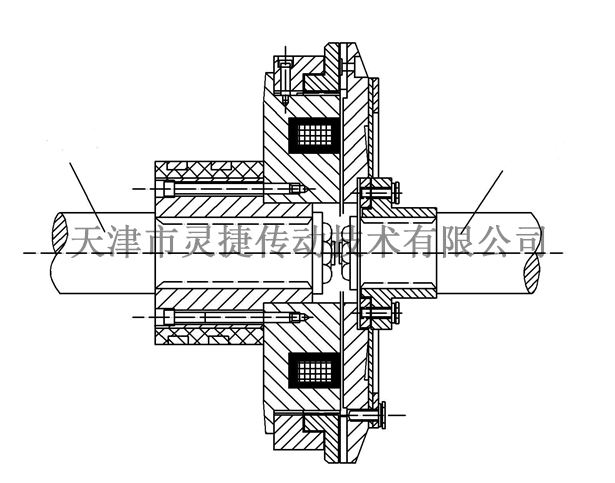

Installation Schematic

Installation Diagram

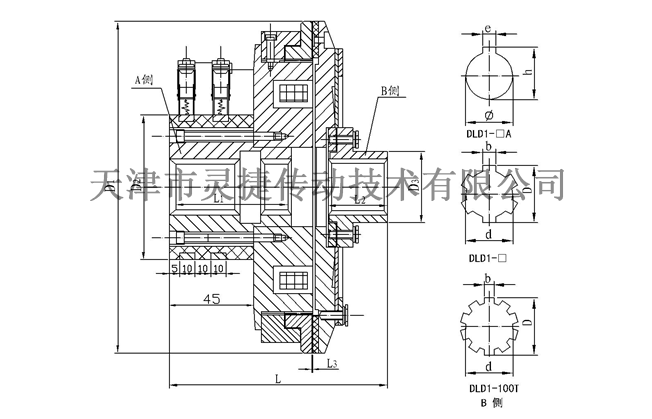

Outline and installation dimensions

Shape and Installation Dimensions

Model

Radial Dimensions

Axial Dimensions

Brush model

Brush ModelD1

D2

D3

L

L1

L2

L3

Δ

DLD1-100

420

170

90

212

105

75

0.7

0.8±0.1

DS-010

DLD1-100A

420

170

90

212

105

75

0.7

0.8±0.1

DLD1-100T

420

170

60

216

117

58

0.7

0.8±0.1

DLD1-160A

480

200

110

259

110

100

0.8

1±0.1

DLD1-160AT

480

200

100

270

110

110

0.8

1±0.1

Model

轴孔尺寸Dimensions of the Shaft Hole

A侧 A Side

B侧 B Side

D

d

b

Φ

h

e

D

d

b

Φ

h

e

DLD1-100

600 0.03

540 0.2

140.045 0.105

600 0.03

540 0.2

140.045 0.105

DLD1-100A

60H7

64.40 0.2

18JS9

60H7

64.40 0.2

18JS9

DLD1-100T

600 0.03

540 0.2

140.045 0.105

380 0.027

330 0.34

60.017 0.040

DLD1-160A

65H7

70.6H11

18JS9

75H7

81.1H11

20JS9

DLD1-160AT

70H7

74.30 0.2

20

55H7

58.60 0.2

160 0.035

Product inquiry

The company has a product research and development department composed of experts, senior engineers and other professional and technical personnel. It is engaged in research and development and has perfect research and development test equipment. At present, the products reach more than 100 series of nearly 1,000 specifications, and the force distance ranges from 0.1N. m ~ 250000N.m. The company has been rated as a high-tech enterprise by the state for more than ten consecutive years, and a number of R & D projects have been established locally and have received municipal financial support.

Service Hotline:

Sales Department: Xu Jie

Sales Phone:+86-22-26616372, +86-22-26341260, +86 13920613215

Fax: 86-022-26616580

Market Development Department: Li Shuo

Marketing Department Telephone:+86-22-26614130

Technology Department: Yue Chao

Technical Department Telephone:+86-22-26222775 ,+86 18602228435

QQ:1059237223 1611412939

Company Website:www.tjlhq.com

Enterprise E-mail:xzm@tjlhq.com

Company address: No.6, Zone B, South Jifeng Road, Hongcang City Industrial Park, Yanji Daohong, Beichen District, Tianjin