Share

- Details

-

Detailed explanation of 1. electromagnetic power-off brake (power-off brake): Special customization is required. It is composed of yoke body, excitation coil, spring, brake disc, armature, gear sleeve, manual release device, etc. The electromagnetic power-off brake is an electromagnetic pull-in when energized. When the power is off, the spring is pressurized to realize friction braking. It is mainly used for small and light motors such as micro motors, servo motors, stepping motors, and electric forklift motors.

The working principle of the 2. electromagnetic power-off brake (power-off brake): After the coil is powered off, under the action of the spring force, friction is generated between the friction disc, the base (or connecting plate), and the armature, and then the drive shaft is driven by the gear sleeve After the coil is energized, the armature is attracted to the magnetic roller under the action of electromagnetic force, which in turn loosens the friction disc to achieve the purpose of releasing the brake.

3. electromagnetic power-off brake (power-off brake) features: simple and compact structure, low heat and low noise, convenient installation, wide adaptability, low noise, high working frequency, sensitive action, reliable braking and fast speed.

4. electromagnetic power-off brake (power-off brake) uses and applications: suitable for metallurgy, machine tools, packaging, construction, chemical industry, food, stage, elevators, ships and other machinery as well as in the power-off (anti-risk) braking and other occasions, to achieve fast parking, accurate positioning, safety braking and other purposes.

Electromagnetic power-off brake (power-off brake) has the advantages of compact structure, convenient installation, wide adaptability, low noise, high working frequency, sensitive action, and reliable braking. It is an ideal automatic actuator. It is widely used in metallurgy, construction, chemical industry, food, machine tools, printing, packaging and other mechanical equipment, and in the event of power failure (risk prevention) braking and other occasions.Electromagnetic power loss brake is widely used in metallurgy, construction, chemical industry, food, machine tools, printing, packaging and other machinery, and in the power failure (anti-risk) braking and other occasions. This kind of brake has the advantages of compact structure, convenient installation, wide adaptability, low noise, high working frequency, sensitive action, reliable braking, etc., and is an ideal automatic actuator.

An electric motor is a device that converts electrical energy into mechanical energy. The starting process of the motor will undergo a state transition from static to dynamic; after the motor is powered off during operation, it will undergo a transition from dynamic to static due to inertia. Most equipment has no requirement for the length of time from moving to static, but some equipment such as elevators, cranes, automated production lines, etc. must be stopped within a very short period of time after power failure, which introduces our topic today, motor brake control.

The braking control of the motor is completed by the electromagnetic power-off brake, which is divided into two categories: power-on brake and power-off brake. The power-on brake is used for braking occasions requiring precise positioning, and the power-off brake is used for occasions where the equipment must be reliably stopped after power failure: that is, if the equipment cannot be stopped in time after power failure, it will cause casualties, equipment damage, product scrapping and other serious accidents that endanger safe production.

The working mechanism of the electromagnetic power-off brake is that the brake does not restrict the shaft when the motor is powered on, and when the motor is powered off or the motor is powered off for any reason, the brake function is activated, the motor shaft is locked, and the motor rotor is realized in a short time The motor rotor is converted from dynamic to static, and the equipment is transferred to a reliable parking state.

The motor brake is an electromagnetic brake, which is composed of three parts: excitation, magnetic conductivity, guidance and reset linear motion mechanism. Specific to the power-off electromagnetic brake for motors, there are parts such as yokes, excitation coils, springs, brake discs, armatures, splines and spline sleeves, and screws for installation and locking.

Main performance parameters

Main Technical DataSpecifications Model

0.6

1.2

2.5

5

10

20

40

Rated Torque

6

12

26

50

100

200

400

Rated voltage Rated Voltage D.C.V

96

96

96

96

96

96

96

Coil power (20 ℃)W

25

40

58

59

83

129

196

Max Allowed Speed( r/min)

3000

3000

3000

3000

3000

3000

3000

Note: the rated working voltage can be specially ordered by the user

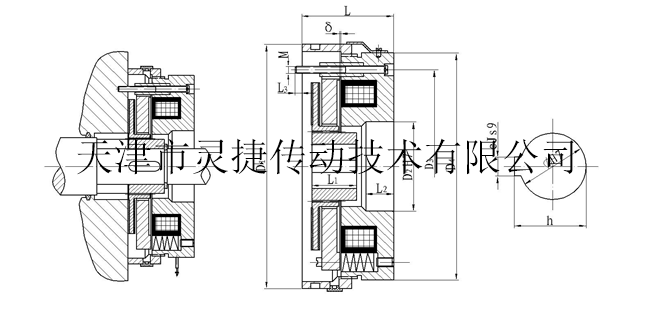

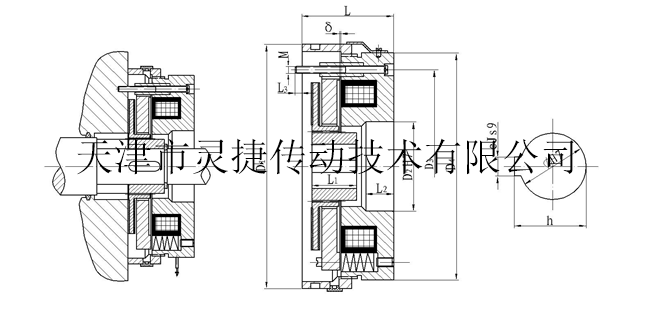

Note:The fixed working voltage may by the user special ordersInstallation Schematic

Installation Diagram

Shape and installation dimensions

Shape and Installation DimensionsSpecifications Model

Radial Dimensions

Axial Dimensions

D1

D2

D3

D4

Φ

h

e

L

L1

L2

L3

M

Δ

0.6

97.5

28

72

86

10

11.40 0.1

3

35.3

20

8.5

5

33M4

0.3

1.2

113.5

42

90

104.5

20

22.80 0.1

6

40.7

20

10

6

33M5

0.35

2.5

142.5

47

112

131.5

20

22.80 0.1

6

44.5

25

15

8

33M6

0.4

5

164.5

55

124

146

25

28.30 0.2

8

58

30

15

8

33M6

0.45

10

198

80

156

183

30

33.30 0.2

8

68.2

35

20

12

33M8

0.5

20

219

85

175

201

40

43.30 0.2

12

74.2

35

20

9

63M8

0.6

40

274

100

215

255

50

53.80 0.2

14

95.6

50

31

12

63M8

0.8

DHM4 electromagnetic power-off brake

Classification

Keyword

Electromagnetic power-loss clutch

- Details

-

Detailed explanation of 1. electromagnetic power-off brake (power-off brake): Special customization is required. It is composed of yoke body, excitation coil, spring, brake disc, armature, gear sleeve, manual release device, etc. The electromagnetic power-off brake is an electromagnetic pull-in when energized. When the power is off, the spring is pressurized to realize friction braking. It is mainly used for small and light motors such as micro motors, servo motors, stepping motors, and electric forklift motors.

The working principle of the 2. electromagnetic power-off brake (power-off brake): After the coil is powered off, under the action of the spring force, friction is generated between the friction disc, the base (or connecting plate), and the armature, and then the drive shaft is driven by the gear sleeve After the coil is energized, the armature is attracted to the magnetic roller under the action of electromagnetic force, which in turn loosens the friction disc to achieve the purpose of releasing the brake.

3. electromagnetic power-off brake (power-off brake) features: simple and compact structure, low heat and low noise, convenient installation, wide adaptability, low noise, high working frequency, sensitive action, reliable braking and fast speed.

4. electromagnetic power-off brake (power-off brake) uses and applications: suitable for metallurgy, machine tools, packaging, construction, chemical industry, food, stage, elevators, ships and other machinery as well as in the power-off (anti-risk) braking and other occasions, to achieve fast parking, accurate positioning, safety braking and other purposes.

Electromagnetic power-off brake (power-off brake) has the advantages of compact structure, convenient installation, wide adaptability, low noise, high working frequency, sensitive action, and reliable braking. It is an ideal automatic actuator. It is widely used in metallurgy, construction, chemical industry, food, machine tools, printing, packaging and other mechanical equipment, and in the event of power failure (risk prevention) braking and other occasions.Electromagnetic power loss brake is widely used in metallurgy, construction, chemical industry, food, machine tools, printing, packaging and other machinery, and in the power failure (anti-risk) braking and other occasions. This kind of brake has the advantages of compact structure, convenient installation, wide adaptability, low noise, high working frequency, sensitive action, reliable braking, etc., and is an ideal automatic actuator.

An electric motor is a device that converts electrical energy into mechanical energy. The starting process of the motor will undergo a state transition from static to dynamic; after the motor is powered off during operation, it will undergo a transition from dynamic to static due to inertia. Most equipment has no requirement for the length of time from moving to static, but some equipment such as elevators, cranes, automated production lines, etc. must be stopped within a very short period of time after power failure, which introduces our topic today, motor brake control.

The braking control of the motor is completed by the electromagnetic power-off brake, which is divided into two categories: power-on brake and power-off brake. The power-on brake is used for braking occasions requiring precise positioning, and the power-off brake is used for occasions where the equipment must be reliably stopped after power failure: that is, if the equipment cannot be stopped in time after power failure, it will cause casualties, equipment damage, product scrapping and other serious accidents that endanger safe production.

The working mechanism of the electromagnetic power-off brake is that the brake does not restrict the shaft when the motor is powered on, and when the motor is powered off or the motor is powered off for any reason, the brake function is activated, the motor shaft is locked, and the motor rotor is realized in a short time The motor rotor is converted from dynamic to static, and the equipment is transferred to a reliable parking state.

The motor brake is an electromagnetic brake, which is composed of three parts: excitation, magnetic conductivity, guidance and reset linear motion mechanism. Specific to the power-off electromagnetic brake for motors, there are parts such as yokes, excitation coils, springs, brake discs, armatures, splines and spline sleeves, and screws for installation and locking.

Main performance parameters

Main Technical DataSpecifications Model

0.6

1.2

2.5

5

10

20

40

Rated Torque

6

12

26

50

100

200

400

Rated voltage Rated Voltage D.C.V

96

96

96

96

96

96

96

Coil power (20 ℃)W

25

40

58

59

83

129

196

Max Allowed Speed( r/min)

3000

3000

3000

3000

3000

3000

3000

Note: the rated working voltage can be specially ordered by the user

Note:The fixed working voltage may by the user special ordersInstallation Schematic

Installation Diagram

Shape and installation dimensions

Shape and Installation DimensionsSpecifications Model

Radial Dimensions

Axial Dimensions

D1

D2

D3

D4

Φ

h

e

L

L1

L2

L3

M

Δ

0.6

97.5

28

72

86

10

11.40 0.1

3

35.3

20

8.5

5

33M4

0.3

1.2

113.5

42

90

104.5

20

22.80 0.1

6

40.7

20

10

6

33M5

0.35

2.5

142.5

47

112

131.5

20

22.80 0.1

6

44.5

25

15

8

33M6

0.4

5

164.5

55

124

146

25

28.30 0.2

8

58

30

15

8

33M6

0.45

10

198

80

156

183

30

33.30 0.2

8

68.2

35

20

12

33M8

0.5

20

219

85

175

201

40

43.30 0.2

12

74.2

35

20

9

63M8

0.6

40

274

100

215

255

50

53.80 0.2

14

95.6

50

31

12

63M8

0.8

Product inquiry

The company has a product research and development department composed of experts, senior engineers and other professional and technical personnel. It is engaged in research and development and has perfect research and development test equipment. At present, the products reach more than 100 series of nearly 1,000 specifications, and the force distance ranges from 0.1N. m ~ 250000N.m. The company has been rated as a high-tech enterprise by the state for more than ten consecutive years, and a number of R & D projects have been established locally and have received municipal financial support.

Service Hotline:

Sales Department: Xu Jie

Sales Phone:+86-22-26616372, +86-22-26341260, +86 13920613215

Fax: 86-022-26616580

Market Development Department: Li Shuo

Marketing Department Telephone:+86-22-26614130

Technology Department: Yue Chao

Technical Department Telephone:+86-22-26222775 ,+86 18602228435

QQ:1059237223 1611412939

Company Website:www.tjlhq.com

Enterprise E-mail:xzm@tjlhq.com

Company address: No.6, Zone B, South Jifeng Road, Hongcang City Industrial Park, Yanji Daohong, Beichen District, Tianjin