Share

- Details

-

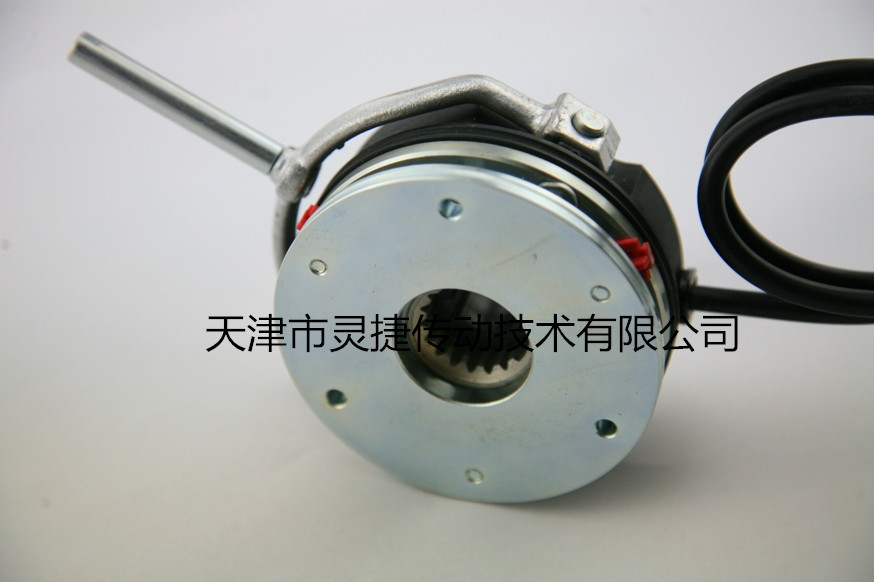

Electromagnetic power loss brake is widely used in metallurgy, construction, chemical industry, food, machine tools, printing, packaging and other machinery, and in the power failure (anti-risk) braking and other occasions. This kind of brake has the advantages of compact structure, convenient installation, wide adaptability, low noise, high working frequency, sensitive action, reliable braking, etc., and is an ideal automatic actuator.

Main rated parameters

Rated torque, rated power, on-time, off-time, working air gap, rated voltage, etc.

Main materials

The iron core and armature are mostly made of No. 10 steel. For large brakes, No. 8 steel is mostly used. The windings generally use F-grade heat-resistant grades. The friction disc generally requires a friction coefficient of more than 0.5. There are also springs.

Working principle

The brake is externally connected with a half-wave rectifier to rectify single-phase alternating current into direct current. After the winding is energized, a magnetic field is generated, which attracts the armature back, and the armature compresses the spring fixed in the core. When the power is lost, the winding discharges, the spring ejects the armature, and the armature generates braking torque on the friction disc to stop the motor.

The electromagnetic power-off brake can operate reliably under the following conditions

The electromagnetic power-off brake is mainly composed of a magnetic yoke, armature, connecting plate, coil, spring, abrasive plate, gear sleeve, manual release installation and other secondary parts. The magnetic yoke is installed on the base or connecting plate by a device screw. After adjusting the air gap δ to the specified value, the coil and spring are installed in the magnetic yoke. The armature can move along the axial direction. The gear sleeve meshes with the internal teeth of the abrasive disc. When the coil is powered off, under the action of the spring force, the abrasive disc and the armature, the base or the connecting plate have a rubbing force, which is transmitted to the drive shaft through the gear sleeve for braking. When the coil is energized, under the action of electromagnetic force, the armature is attracted to the magnetic yoke, The abrasive disc is released, and the drive shaft is released from braking, which is in a free form.

Main performance parameters and installation dimensions

Seat Number

b

dH7 standard

d1

d2

d3H7

d5

d6j7

d7

d8

d10

d11

d12

d13

d14

d15

di

da

06

88

10/11/12/14/15

3 × M4

72

25

91

87

87

52

31

8

9.6

4 × M4

37.7

3 × 4.5

40

60

08

106.5

11/12/14/15/20

3 × M5

90

32

106

102

102

60

41

8

9.6

4 × M5

49

3 × 5.5

47

77

10

132

11/12/14/15/20

3 × M6

112

42

134

130

130

68

45

10

12

4 × M5

54

3 × 6.6

66

95

12

152

20/25

3 × M6

132

50

155

150

150

82

52

10

12

4 × M5

64

3 × 6.6

70

115

14

169

20/25/30

3 × M8

145

60

169

165

165

92

55

12

14

4 × M6

75

3 × 9

80

124

16

189

25/30/35/38*

3 × M8

170

68

195

190

190

102

70

12

/

4 × M6

85

3 × 9

104

149

18

216

30/35/40/45

3 × M8

196

75

222

217

217

116

77

14

/

4 × M8

95

6 × 9

129

174

20

249

35/40/45/50

3 × M10

230

85

259

254

254

135

90

14

/

4 × M10

110

6 × 11

148

206

25

296

40/45/50/55/60/65/70*

3 × M10

278

115

307

302

302

165

120

16

/

4 × M10

140

6 × 11

199

254

30

356

65/70/75/80

3 × M10

325

140

365

363

363

200

145

18

/

4 × M10

180

6 × 11

230

300

■Standard voltage: 24VDC、180VDC、205VDC。

■MK: Rated torque (Nm) This value is measured when the relative speed Δn = 100rpm.

■P: at 20.C coil power (W).

■Keyway standard reference GB/T1095The choice of shaft diameter depends on the type of load. Refer to GB/T1566 for the standard of keyway marked with * for shaft hole.

■L1is the leader length.

■Unit: mm.

Seat Number

h

h1 min

h1 max

h2

h3

h4

h5

h6

h7

h8

L

L1

S

Smax

Α

Beta

06

36.3

39.3

43.25

1

6

15.8

107

54.5

56.3

1

18

500

0.2

0.5

25°

12°

08

42.8

46.8

50.8

1.5

7

16.3

116

63

65

1

20

500

0.2

0.5

25°

10°

10

48.4

52.4

55.9

2

9

27.4

132

73.8

77.8

1

20

500

0.2

0.5

25°

9°

12

54.9

58.9

67.53

2

9

29.4

161

85

88.5

1.5

25

500

0.3

0.75

25°

10°

14

66.3

71.3

77.3

2

11

33

195

98

101.5

1.5

30

500

0.3

0.75

25°

9°

16

72.5

77.5

85.5

2.25

11

37.5

240

/

/

1.5

30

700

0.4

0.75

25°

10°

18

83.1

89.1

97.09

2.75

11

41.1

279

/

/

2

35

700

0.4

1

25°

9°

20

97.6

104.6

114.6

3.5

11

47.6

319

/

/

2

40

700

0.4

1

25°

10°

25

106.7

115.7

127.7

4.5

12.5

57.7

445

/

/

2.5

50

700

0.5

1.2

25°

10°

30

134.5

144

156

5

20

68

832

/

/

3

75

1000

0.6

1.2

25°

10°

■Unit: mm

DHM3-F type electromagnetic power-off brake

Classification

Keyword

Electromagnetic power-loss clutch

- Details

-

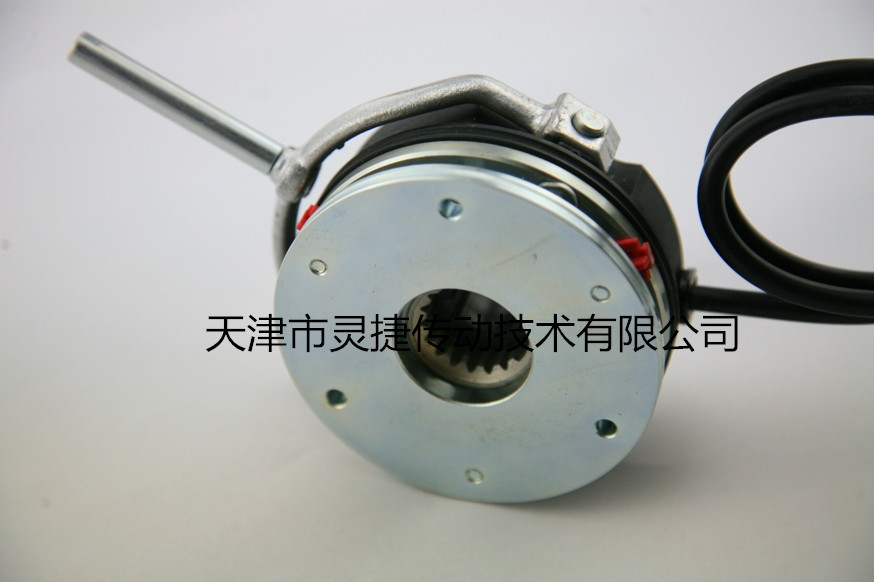

Electromagnetic power loss brake is widely used in metallurgy, construction, chemical industry, food, machine tools, printing, packaging and other machinery, and in the power failure (anti-risk) braking and other occasions. This kind of brake has the advantages of compact structure, convenient installation, wide adaptability, low noise, high working frequency, sensitive action, reliable braking, etc., and is an ideal automatic actuator.

Main rated parameters

Rated torque, rated power, on-time, off-time, working air gap, rated voltage, etc.

Main materials

The iron core and armature are mostly made of No. 10 steel. For large brakes, No. 8 steel is mostly used. The windings generally use F-grade heat-resistant grades. The friction disc generally requires a friction coefficient of more than 0.5. There are also springs.

Working principle

The brake is externally connected with a half-wave rectifier to rectify single-phase alternating current into direct current. After the winding is energized, a magnetic field is generated, which attracts the armature back, and the armature compresses the spring fixed in the core. When the power is lost, the winding discharges, the spring ejects the armature, and the armature generates braking torque on the friction disc to stop the motor.

The electromagnetic power-off brake can operate reliably under the following conditions

The electromagnetic power-off brake is mainly composed of a magnetic yoke, armature, connecting plate, coil, spring, abrasive plate, gear sleeve, manual release installation and other secondary parts. The magnetic yoke is installed on the base or connecting plate by a device screw. After adjusting the air gap δ to the specified value, the coil and spring are installed in the magnetic yoke. The armature can move along the axial direction. The gear sleeve meshes with the internal teeth of the abrasive disc. When the coil is powered off, under the action of the spring force, the abrasive disc and the armature, the base or the connecting plate have a rubbing force, which is transmitted to the drive shaft through the gear sleeve for braking. When the coil is energized, under the action of electromagnetic force, the armature is attracted to the magnetic yoke, The abrasive disc is released, and the drive shaft is released from braking, which is in a free form.

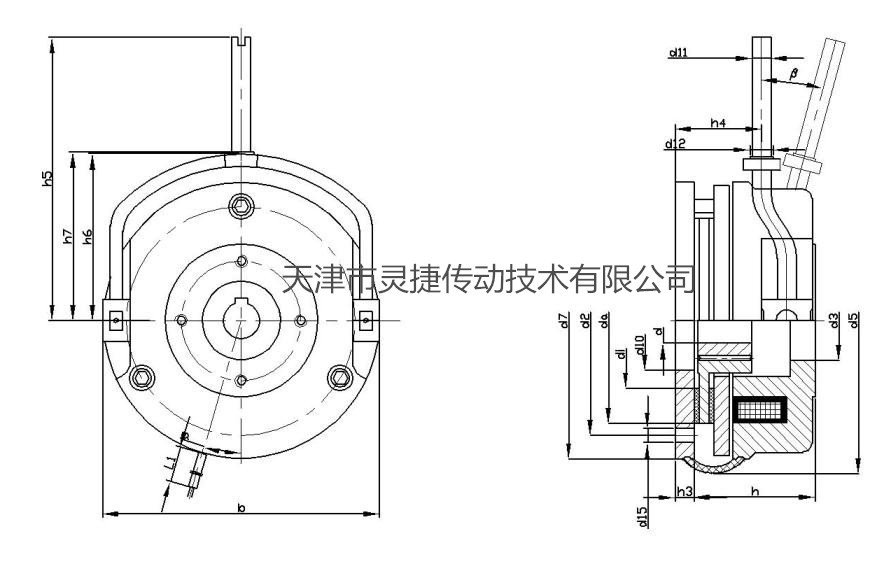

Main performance parameters and installation dimensions

Seat Number

b

dH7 standard

d1

d2

d3H7

d5

d6j7

d7

d8

d10

d11

d12

d13

d14

d15

di

da

06

88

10/11/12/14/15

3 × M4

72

25

91

87

87

52

31

8

9.6

4 × M4

37.7

3 × 4.5

40

60

08

106.5

11/12/14/15/20

3 × M5

90

32

106

102

102

60

41

8

9.6

4 × M5

49

3 × 5.5

47

77

10

132

11/12/14/15/20

3 × M6

112

42

134

130

130

68

45

10

12

4 × M5

54

3 × 6.6

66

95

12

152

20/25

3 × M6

132

50

155

150

150

82

52

10

12

4 × M5

64

3 × 6.6

70

115

14

169

20/25/30

3 × M8

145

60

169

165

165

92

55

12

14

4 × M6

75

3 × 9

80

124

16

189

25/30/35/38*

3 × M8

170

68

195

190

190

102

70

12

/

4 × M6

85

3 × 9

104

149

18

216

30/35/40/45

3 × M8

196

75

222

217

217

116

77

14

/

4 × M8

95

6 × 9

129

174

20

249

35/40/45/50

3 × M10

230

85

259

254

254

135

90

14

/

4 × M10

110

6 × 11

148

206

25

296

40/45/50/55/60/65/70*

3 × M10

278

115

307

302

302

165

120

16

/

4 × M10

140

6 × 11

199

254

30

356

65/70/75/80

3 × M10

325

140

365

363

363

200

145

18

/

4 × M10

180

6 × 11

230

300

■Standard voltage: 24VDC、180VDC、205VDC。

■MK: Rated torque (Nm) This value is measured when the relative speed Δn = 100rpm.

■P: at 20.C coil power (W).

■Keyway standard reference GB/T1095The choice of shaft diameter depends on the type of load. Refer to GB/T1566 for the standard of keyway marked with * for shaft hole.

■L1is the leader length.

■Unit: mm.

Seat Number

h

h1 min

h1 max

h2

h3

h4

h5

h6

h7

h8

L

L1

S

Smax

Α

Beta

06

36.3

39.3

43.25

1

6

15.8

107

54.5

56.3

1

18

500

0.2

0.5

25°

12°

08

42.8

46.8

50.8

1.5

7

16.3

116

63

65

1

20

500

0.2

0.5

25°

10°

10

48.4

52.4

55.9

2

9

27.4

132

73.8

77.8

1

20

500

0.2

0.5

25°

9°

12

54.9

58.9

67.53

2

9

29.4

161

85

88.5

1.5

25

500

0.3

0.75

25°

10°

14

66.3

71.3

77.3

2

11

33

195

98

101.5

1.5

30

500

0.3

0.75

25°

9°

16

72.5

77.5

85.5

2.25

11

37.5

240

/

/

1.5

30

700

0.4

0.75

25°

10°

18

83.1

89.1

97.09

2.75

11

41.1

279

/

/

2

35

700

0.4

1

25°

9°

20

97.6

104.6

114.6

3.5

11

47.6

319

/

/

2

40

700

0.4

1

25°

10°

25

106.7

115.7

127.7

4.5

12.5

57.7

445

/

/

2.5

50

700

0.5

1.2

25°

10°

30

134.5

144

156

5

20

68

832

/

/

3

75

1000

0.6

1.2

25°

10°

■Unit: mm

Product inquiry

The company has a product research and development department composed of experts, senior engineers and other professional and technical personnel. It is engaged in research and development and has perfect research and development test equipment. At present, the products reach more than 100 series of nearly 1,000 specifications, and the force distance ranges from 0.1N. m ~ 250000N.m. The company has been rated as a high-tech enterprise by the state for more than ten consecutive years, and a number of R & D projects have been established locally and have received municipal financial support.

Service Hotline:

Sales Department: Xu Jie

Sales Phone:+86-22-26616372, +86-22-26341260, +86 13920613215

Fax: 86-022-26616580

Market Development Department: Li Shuo

Marketing Department Telephone:+86-22-26614130

Technology Department: Yue Chao

Technical Department Telephone:+86-22-26222775 ,+86 18602228435

QQ:1059237223 1611412939

Company Website:www.tjlhq.com

Enterprise E-mail:xzm@tjlhq.com

Company address: No.6, Zone B, South Jifeng Road, Hongcang City Industrial Park, Yanji Daohong, Beichen District, Tianjin